I have had many successful Cuts cutting 16 and 14 gauge steel. I’m now attempting to cut 1/4 inch 6061 aluminum plate. I have made three attempts with different specs. The final attempt which I’m not happy at all with using a razor cut 45 at 45 amps, feed rate 20 in per minute. At least it did cut all the way through on the last time. I am also grounded directly to the plate. I realize it’s time for tip change but it will be my third.

IMG_20180928_135245451|375x500

O man. That looks a little rough. I was hoping these things would cut aluminum a little smoother than that. I haven’t looked but is quarter inch thick aluminum near the capacity of these? I have a hypotherm but mine is only a 45 amp machine also

I did a piece of 1/4” and it did not come out great as well. I just think it may be to thick for the razorweld to produce a clean cut. I did do 3/16 and 1/8 and the cuts came out ten times better. If I were you, the thickest aluminum I would cut is probably 3/16.

This was 3/16 45 amps 30ipm

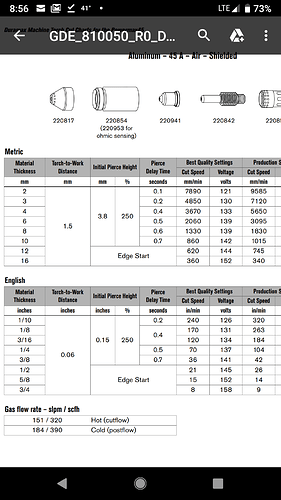

It looks like 1/4" is the thickest you can cut without an edge start only on my cut chart. Have you played with your pierce delay? Maybe your machine is only gouging before it starts to move?

You know aluminum dose not not take much heat the thickest is less and 3/16 is just a little faster so 30 imp looks good

The 3/16 inch sheet aluminum should can be cutted