I have a design and there are 4 small cuts to make bending tabs easier but when I run it through CAM, everything is offset for the cuts like it should be but I need these 4 bend cuts to cut on centerline…how to you do that?

I was just playing with this in fusion to see what I could figure out. I think the best thing to do is create a tool with a 0.001" kerf and apply it to the single lines with no lead in/lead out. This will cut close enough to right on the line that you would not be able to tell the difference.

Are you designing the original part in fushion or bringing in a dxf file from another program? Several ways you could go about your situation. Is this thicker material? What I do 1/8 or more which still needs bent with a press brake is say its a square and you want a bend right in the middle. What I do is make a little relief or triangle divot in the part on each side where it will be bent. sometimes I’ll add a large single cut like you are inquiring about. I’m not sure if there is a better way to go about this last suggestion or not. I will compensate for circles or some parts in my vector program by adding the kerf into the actual dimensions. So Say I want a 4" wide part, I’ll program it as 4.06 to make up for the .06 kerf I normally get.

I just started playing around with creating different tools and kerfs, but it still comes down to what tips, off contact and material you are cutting that determine a true kerf width.

If you wanted only some parts to cut at a diff speed or have no lead in etc, I haven’t tried it but I wander if you can create two different setups in fushion. Never tried it. even if you cut right in the middle and your plasma has a .06 kerf you are getting .03 on each side of that straight line.

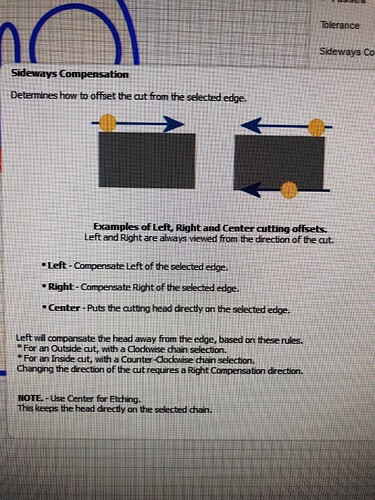

This is a dxf’s that was drawn in another program and imported into fusion. My son just took over my company where for the last 12 years I did all the drawing and programming for our Busellato Jet 200 CNC Router in our woodworking business. With that machine I was able to program in different tools and drills within the same program but have not found that option in Fusion. In situations where we had to machine a part and reposition it for another process, I could “stack” programs to run the first program then pause for adjustment the hit run and off it goes. You have the choice is setting up Cutting, 2D Profile, Passes Tab, Sideways Compensation to choose Right, Left or Center if the line. So far, I see two options, one is to alter the original drawing by moving the bend line cuts offset so when imported in and tool path is generated the torch actually cuts in the correct position OR create 2 separate programs, one to cut the the bend marks on center line and then one to cut on the left for an offset and then run the first one, then the second one. Maybe it would be possible to generate the 2 programs and then edit them in word and merge them together to run one right after the other and maybe this can be done in Frusion…just haven’t found it yet

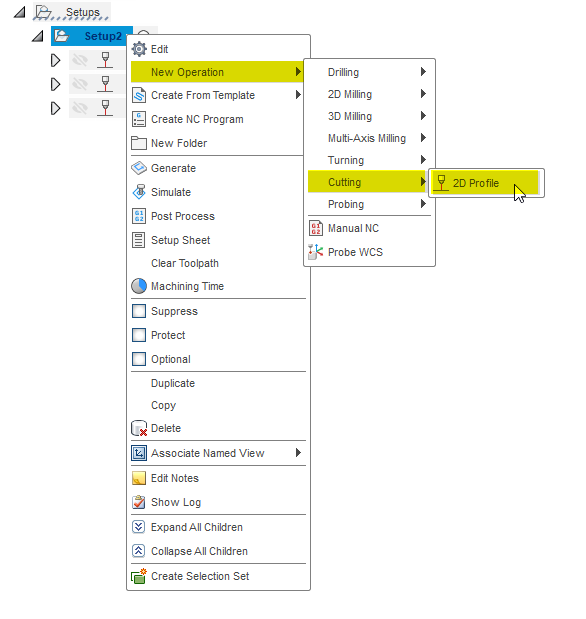

You can do 2 different cuts with 2 different “tools” in fusion. Do your first cut with your 0.001 kerf tool and select just your bend lines. Add another cut and use your normal kerf tool and cut the outer profile.

I’ll have to try that, but you wouldn’t have to do a .001 offset as when making a cut you have a choice of cutting left, right or on center of the line. This was the same as with the CNC router software.

Awesome! Sounds like you answered your own question then.

Well I havent actually tried it yet

I just tried it. Works perfectly. Just make sure to uncheck lead in/lead out and change the pierce clearance to 0.0 for the center compensation cuts.

I think we need to schedule a field trip. I nice weekend somewhere where a bunch of us can fly, drive or somehow arrive and do a live fusion 360 session. Perhaps with some micro brews in the evening.

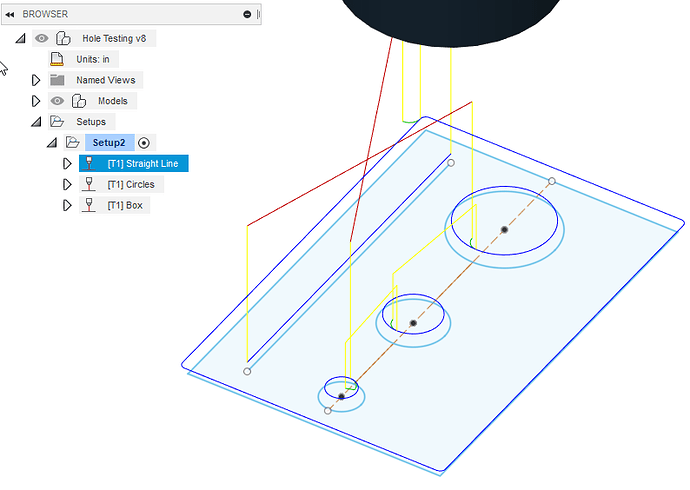

Okay, just in case anyone is curious. I was trying to figure out how to use multiple tools and or cut types in a single program. Simply right click your Setup. Then add a new cutting operation (see below). When you simulate and finally process your post, make sure that you have the Setup selected and not simply an individual 2D profile selected. Everything is contained together in a single file! You may not be excited, but I definitely am! In my example, I have a center line cut at a faster speed, circles with Left offset, including a lead in…all done at a lower IPM, and finally the box with a different IPM.