so im trying to cut my first sign everything is loaded into software correctly. i am currently running a thermal dynamics cutmaster 42 and i start the cutting process it cuts first letter, pierces the next hole, then proceeds to cut out does whole letter then pierces the next hole for the next letter .

how to i solve this cutting off issue is it some thing with machine (cutmaster42) or maybe i missed something in the software? help!

Are all the letters supposed to be cut out at once with no break in between?

Typically when one cuts out letters, it does each letter individually.

Post a screenshot or picture of the file that you’re trying to cut

no they are being cut individually runs the first letter pierces the second n immediately shuts off just runs air

It is set to 4T? It needs to be set to 2T. Not familiar with your plasma cutter but the switch should be on the front.

its a thermal dynamics cutmaster 42

Send me a picture of the front.

there are no features to select other than amperage

I was trying to download a manual. Victor has sold it sole to the Chinese mainland.

Does the torch keep burning during the move to the next letter?

no hits the pierce n stops firing then runs letter off goes to next letter does pierce then cuts out again then repeats

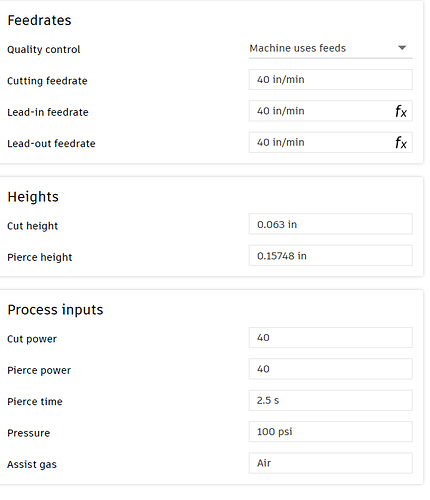

What are you cutting? List all your setpoints.

Pierce delay, cut height, etc.

Air Pressure during cut, pierce delay…

Thermal Dynamics plasma cutters are problematic with CNC tables. Some of them have a safety feature that requires a very long pierce delay on the first cut. Sheetcam has a modified post processor to deal with this issue.

I’m not sure this is your issue, but I’m still not fully understanding your description. Are you saying that it fires, pierces the metal and then stops firing?

Where is your work clamp(ground) attached? What you describe sounds like the pilot arc and it shuts off because it isn’t transferring to the cutting arc.

Edit: I just saw your settings. 2.5 seconds is a long pierce delay. On a normal plasma cutter, that is long enough for the torch to burn out before moving. It’s even too long for a first pierce on a Thermal Dynamics machine. They need an additional 1.5 seconds, but only on the first pierce.

so try 1.5 seconds? I will check work ground . It will pierce and run the first full letter go to the next pierce then it just shuts off the arc n continues the program

Shorten the pierce delay.

You are going to have to modify your g code or switch to Sheetcam and use the “TD mod retract” version of the Firecontrol v1.6 post processor.

What’s happening is your long pierce delay works for the first pierce, due to the TD safety feature. The rest of the pierces in the program don’t require that long delay and the torch is burning out before it moves.

The modified post processor in Sheetcam allows you to set your pierce delay to the proper length for the rest of the program (let’s say .5 second) and the post processor adds 1.5 seconds to only the first pierce delay.

If you want to continue using Fusion, you’ll have to set your delay to work with the rest of your program and edit the code to change only the first pierce delay.

You may also be able to manually fire the torch before starting your program.

Just a heads up, the only value there that is being used is your feedrate of 40ipm.

Your cut height, pierce height, and pierce delay values in this tool chart are completely ignored and not used. The values for the figures that matter are those that you enter in the box that appears when you go to post process your g-code.

At 40ipm, I assume you’re cutting something like 1/4" thick because that’s really slow for anything thinner.