!

I keep trying to cut something out and it starts great then it cuts out says “LS-THC detected voltage was lost during the cut. I tried to upload pictures but that says file to large. My clamp is connected, states pierce height or cut height are too high. I got this file from Langmuir ready cut. I have checked the lead screws. Any suggestions would be appreciated. I’m new to this so please no smart alec remarks please, I’m frustrated enough. Thanks in advance

What file from Fireshare?

It’s could be a number of things. One of those could be a bad design that has cut lines crossing already cut sections. If the torch crosses an already cut area, it loses the connection to the work clamp and shuts off.

cut ready is never cut ready. you still have to play with settings. on that note, could be that your torch is too high in the mount so it’s giving you a false pierce/cut height. During the initial ihs sequence, if the torch goes down but then rises before it touches the material, then the torch is too high.

but with out any more info, kinda just guessing.

Any chance you can forward (upload) the cut ready file? As others have said, Cut Ready really isn’t. Most files will require some form of modification based on your particular setup.

To get things moving:

What plasma cutter?

What amperage?

If you can upload the (cut) file, we can look and see what stands out.

HighlandWelcome.nc (235.4 KB)

Razorcut45, 35 amp,

What are you trying to cut? Steel, Alum, ? What gauge?

16 g steel. I’m limited to what i have access to where i live. it’s either 14 or 16.

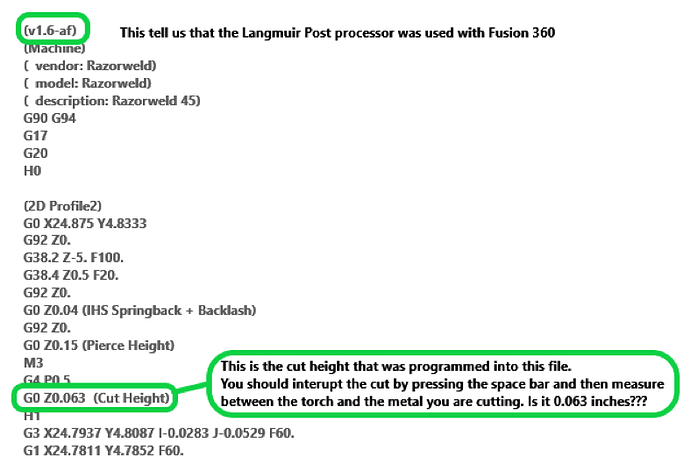

Have you been able to verify your actual cut height? Your cut file has a 0.040" additional adjustment, making your height 0.103", not the 0.063" you’ve called for.

I have not. Honestly i have no idea how to change it. Is there a video or somewhere i can read? Im struggling fusion 360, im struggling with this whole thing. I’m ready to go back to cutting by hand. Being dyslectic doesn’t help much. But i’m not giving up. Not a quitter lol. I really appreciate all of you taking the time. Thank you

Checking your cut height and changing your cut height are two different things.

In this situation, since you are using a file that is already a gcode file, the cut height is already set in it. Here is the first part of your file:

Keep an eye on your compressor pressure. I’ve got a California Air compressor with a 10 gallon tank. It can almost keep up during a cut, but as soon as it gets a little behind I get the same error and it stops. I’ve got an older compressor with a 60 gallon tank that I don’t usually use just because it’s loud. However, if my cut is going to take more than a few minutes, I turn it on also. They are tied into the same air circuit so it kicks in and picks up the slack and I’ve never gotten the error once I started doing this.