TestCoupon.nc (1.0 KB)

16ga correct? Try .06 cut height

.07 delay

.15 pierce height

30 amps

105 ipm

Try those settings

That coupon looks like Stainless Steel

It’s actually .071 , slight thicker than 16

If it’s not SS, use those numbers and cut another coupon. If it is SS ipm 88

Set you springback to .02 currently, its@ .04 . Pierce height is at .15

Sorry .2, my bad.

Do a test on your actual cut height and adjust your spring back and cut height accordingly.

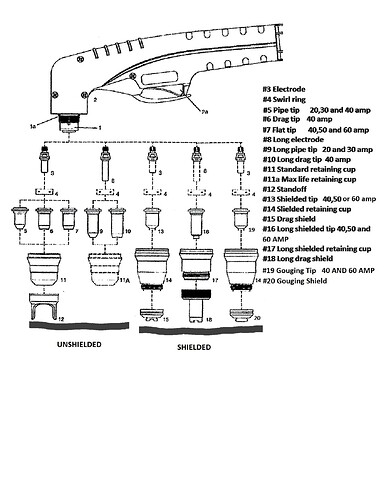

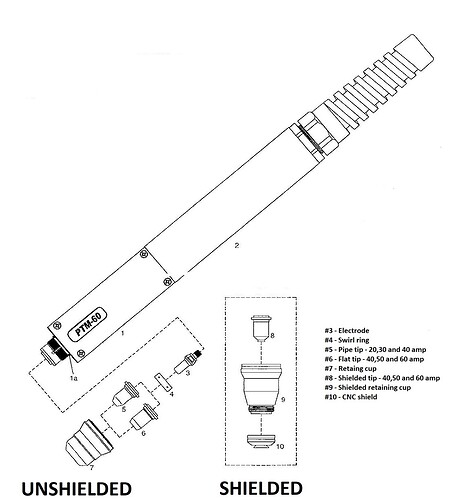

Those are Chinese S45 style consumables and are shot. S45 cutting tips come in sizes of 20, 30 and 40 amp you have a 55 amp plasma cutter.

I would recommend getting Tecmo PT back striking consumables made in Italy.

S45 and PT consumables are what they call blow back start. PT consumables are back striking and S45 are front striking and cause more wear on the cutting tip and electrode.

Here is a picture of all the consumables you can get for the Tecmo PT hand and machine torch’s.

It was brought to my attention that this chrome moly. Cut it like SS try 88 ~90 ipm

Just a note that chromoly gets brittle when plasma cut. If its a race car part that needs a SEMA tag you might want to use a water jet.

Gets welded along most of the plasma cuts anyway so haz grows at that point.

Thank you, I see you are an expert in this area! So it sounds like a good path would be maybe save the 3k on the hypertherm and get a machine torch and proper consumables?

You will need verify that a Primeweld torch will connect to a lotos machine.

@mechanic416 can lead you the right direction and maybe even sell you the torch. His are the genuine tecmo torch not the knockoffs others sell.

I agree with George, one of the wise men here.

Do straight cuts, using FireControl generated code, result in similar poor quality cuts? Does this happen in both X an Y?

The chromium is oxidizing during the cut. That’s why it is black and rough. The plasma cutter should cut it with a nitrogen or F5 gas supply. Just a note that cutting this produces a toxic gas.

Hexavalent chromium, also known as chromium 6 (Cr6), is a toxic form of the metal chromium. It is a cancer-causing chemical affecting the respiratory system, kidneys, liver, skin, and eyes. Can it be done? Yes. Should it be NO? Just my two cents, as usual.

Oh, this is stainless. I’ll step away from the conversation. Thanks for the info.

Chromoly 4130

So this might be new to me. Understood the haz issue with any type flame cut but am surprised a out the insert gas requirement. So are you staying this is a process issue? (Wrong process for material). Or a better torch/consumables would resolve the issue(mostly).

If you cut this with Nitrogen or F5 gas, it would work fine. There is still a health hazard involved. I genuinely believe that putting a piece of mild steel on the plasma cutter would perform fine. The F5 gas will shield the edges from oxidation and produce a better, not perfect, cut. 4130 should be water-jetted or laser-cut. How much do you plan on cutting? Are you fabricating a race car chassis?

I know you got this. I want you to know the hazards.

Regular air on the right, F5 gas on the left