So, my new(ish) machine that I ordered was DOA yesterday so I am waiting on an “actuallly new” machine to be delivered by the Amazon Fairy later today.

In the mean time, I decided to check my cut height as per y’all’s advice.

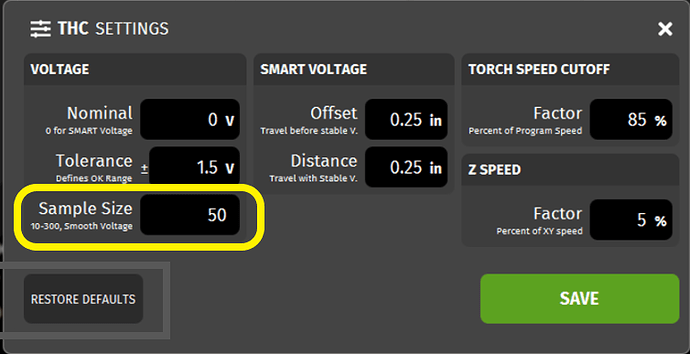

But I got to thinking that I should probably install the THC “thing-a-ma-bobber” before I do that.

I ordered it when I bought the machine, but decided not to install it in order to “keep things as simple as possible” for a noob. My reasoning was that I should get a few successful cuts under my belt before complicating things with the THC.

So it went really well, and it was basically a “plug and play” operation.

I did a few test cuts, and was not very impressed.

I purposely bent up a scrap piece to simulate a warped work piece, and the first result was not stellar.

Here is the before pic of the set up (with my man-made warpage)

Then my first cut…Not impressed.

Second cut was even worse.

So I started analyzing things and I can’t see anything wrong, but since I have almost no idea what I am actually looking for, that is not not surprising.

So I decide to look at the voltages when it’s running. I have no idea what this will accomplish, but at least I will have something to post here.

F’ing ran perfect for some strange reason…I ain’t complaining, just sayin…I have no idea what happened.

With success as a starting point I decide to give the old “cut height test” a whirl.

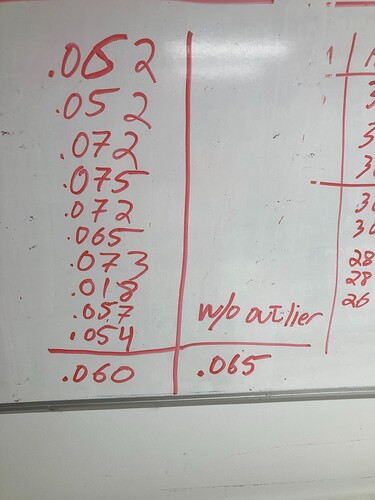

Here are my results. Although technically not “statistically significant” I ran the machine 10 times and stopped the cut about 1 inch into it, and broke out the feeler guages.

The 'outlier" made it perfect, but I don’t like “outlier’s”. However even not including that .018 pass, I am still at .064", so I bet that I am damn close to .060 if you factor in “measurement error”

What say you?