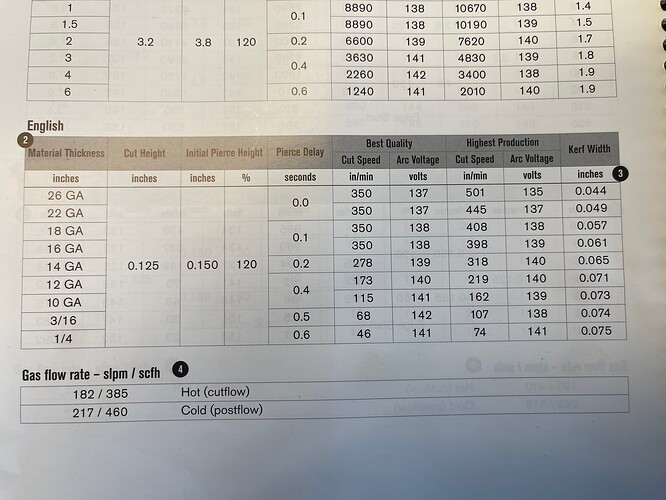

So spec wise I am running a new Hypertherm Powermax 85 sync with the Langmuir XR running Fusion 360. I am basing most all the specs off the Hypertherm user guide shown below and a few things off of Langmuir’s tutorials.

The main issues I’m running into :

When I go to manufacture I get linking constraint problems. Which that I can’t understand why it happens in some circumstances. In the beginning I was assuming it was because it was trying to run paths that were too tight but it’ll do it on things that it really shouldn’t have issues with. The example below the program decided to add these odd Y paths so it just cut into the face for no reason.

The cut quality varies drastically from super straight to super wavy leaving artifacts in odd spots. Even with proper point of entry I’ll get blow outs on corners. I’m not sure if that is a pierce delay issue or height. I am testing with hot rolled at the moment. It doesn’t have really any mill scale. I was also curious if its that sensitive to it.

I feel like it should be able to cut some pretty intricate designs without a lot of issues. I’ve seen some pretty complex things in fireshare so I figure it shouldn’t be running into these types of issues.

I’d add more pictures but it won’t let me. Pretty cool…

Thanks,

Noel