Can you help me with the cut chart for 14 ga. mild steel material because I’m using the ones from the Hypertherm 65A table, but it seems they’re not the right ones. I use firecontrol and crossfire xr

It would help if you told us what plasma cutter you are using.

I am using the hypertherm 65 sync with smart torch.

Why does it seem they’re not right? What is happening?

The only difference should be that you need a longer pierce delay than what is in the Hypertherm chart.

The XR max speed may be lower than the speed in the chart, but there is no way to fix that. Just set it to the max speed of the XR.

Are you using 45 amp consumables or are you using fine cut consumables?

There’s a number on the side of the consumable.

Triple check it’s a consumable for mechanized cutting.

I used 45 amp consumables

@Marino87 the 45 amp consumables on hypertherm sync are optimized for 1/8th to quarter inch material. For materials 10 gauge and less you’re going to want to use the fine cut consumables.

The 45 amp consumables will work on 14 gauge but it’s not it’s optimal cutting range.

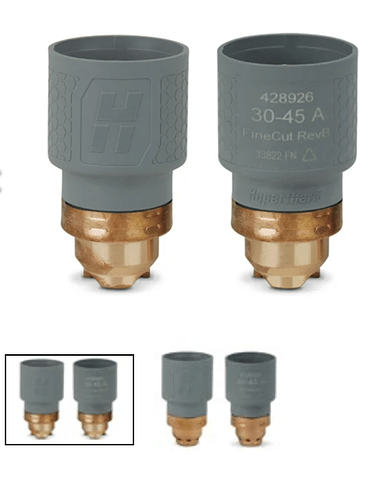

Hypertherm cartridge: SmartSYNC/adapter 45A mechanized cutting #428925 Hypertherm cartridge: SmartSYNC/adapter 45A mechanized cutting #428925

Hypertherm cartridge: SmartSYNC 30-45 A mechanized FineCut #428926 Hypertherm cartridge: SmartSYNC 30-45 A mechanized FineCut #428926

And again triple check that they are the consumables that are gray in colour.

"30-45 A mechanized FineCut

Part number: #428926

FineCut® cartridges produce a narrower kerf on thin mild steel and stainless steel up to 3 mm (10 gauge) which is ideal for fine detail cutting. To maximize cartridge life and performance it is important to select the cartridge that is optimized for the workpiece you are cutting"