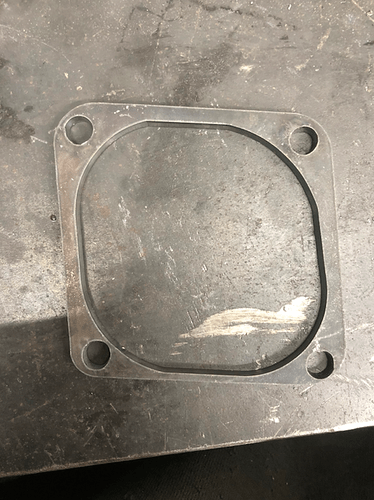

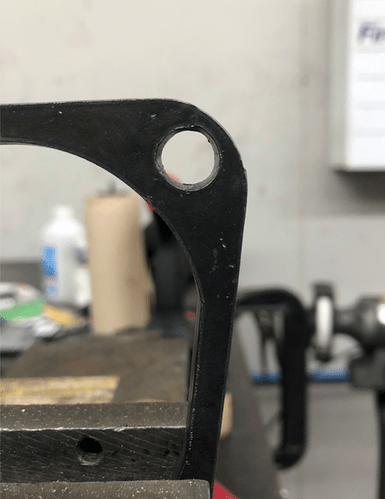

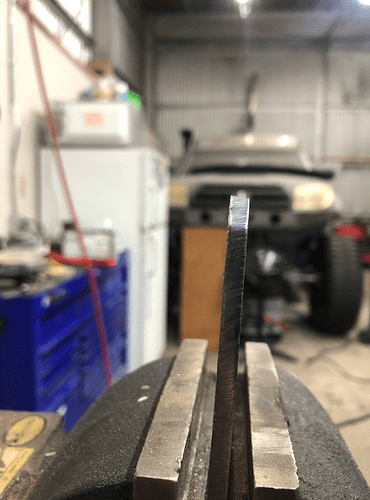

So, I’m starting to get frustrated chasing a constant and consistent bevel that I’m getting on all of my cuts on all sides. I have made sure that the torch is definitely perpendicular to the material and my air should be clean and dry. The following is for 3/16" mild steel. I understand that this plasma cutter is no longer “supported” but I know other people are running them and I’m wondering if this is the cut quality that I should expect or if I have an issue somewhere. Thanks In advance!

Program setup:

- 63 and 60 ipm were tried

- I lowered the cut height from .060" to .055" and raised the air pressure to 65 psi and it helped but didn’t solve it.

- Kerf width is .045"

- Nozzle clearance diameter is .16"

- Head clearance is .04

Here is my setup:

- Crossfire pro (With THC)

- Prime Weld Cut 60 with machine torch and included (new) consumables

- new 5 micron desiccant filter/ regulator

- 50-75 ft 3/8 air line 150 psi from comp. regulated with internal regulator