Just set up my oven and had some questions regarding cure control.

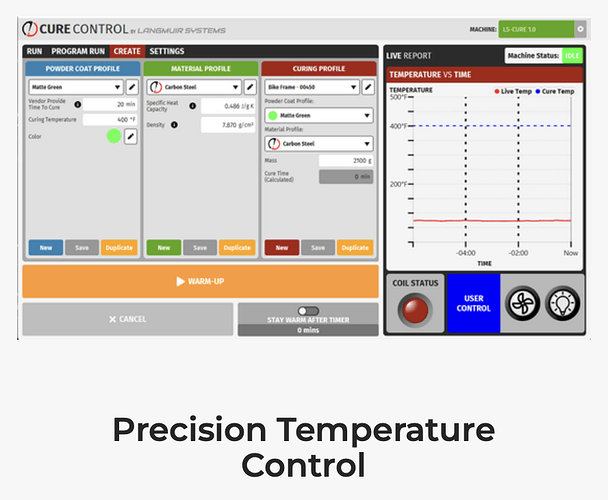

I’m under the impression I can create and save programs for the specific requirements of different powders. There’s an image on the site I posted below showing a tab in cure control called “create” and you can see a color and material profile below. I don’t have that on mine. I just have ‘run’ and ‘settings’. I think you can also control the fan speed. I have the pro electrical kit. The software is up to date.

What am I missing?

That tab view option had to be delayed for the final release as we fix it up. We will be releasing it as a patch in the coming months.

1 Like

My unit has the same screen as yours. Not sure why you would want the other tabs unless you were in a production scenario.

I wish for a 3-inch port in the door with a sliding flap so you could check the part temp without opening the door. It could be an add-on if you wanted it.

@langmuir-sam I will make one and let you and Cole check it out.

1 Like

Yeah I noticed in your pics you had the same screen. I have been using a pretty budget setup for my powder coating and run the same temps for each color, which may be fine, but I was under the impression that not all powders were created equal.

I wish the program would run once the oven reaches temperature. I didn’t notice a beep or alarm when it hit temp earlier.

You are correct not all powders are created equal. Most reputable suppliers will give you spec sheets or list on the label.

I generally use Columbia coatings or prismatic. To me they have the best powder I have used.

I am coating thick items. Sometimes, it takes 20 minutes for the part to stay in there to get to 400°, which is the temperature most Prismatic powders use. That’s why I will fab up a 3” port in the door with a sliding cover. When ever I open the door, it must reheat to the temperature. I must build my confidence in drilling a hole in the door.

1 Like

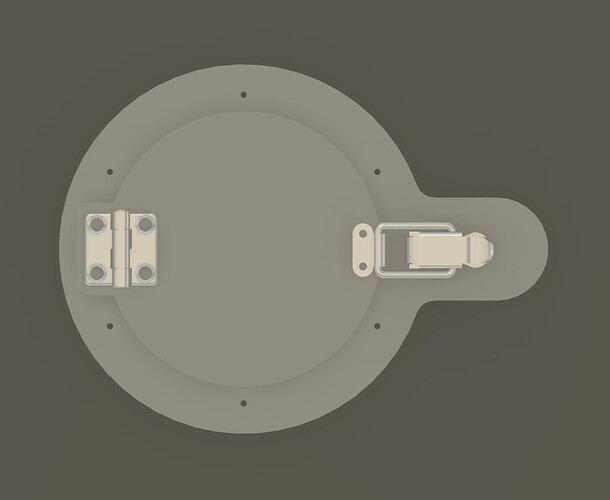

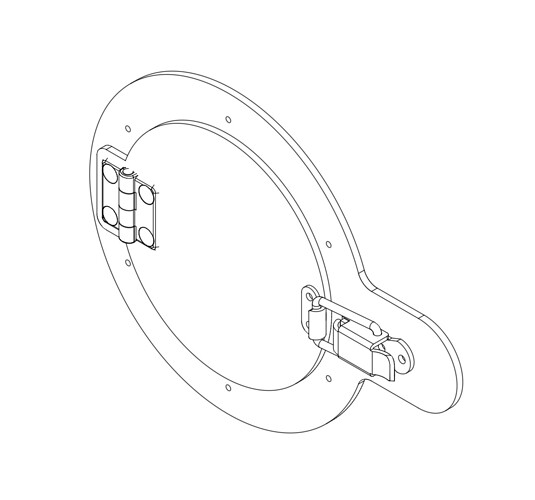

Yeah. I’ve noticed the temp drop quite a bit once the door opens. Yeah didn’t think about bigger thick parts in there. I’m always doing 20ga. A round port might be the easiest because you can just use a hole saw and you won’t have to fuss with cutting 90’ corners. Gonna have to be a pretty big hole to be useful but I think you can get a 4” hole saw. Won’t be fun on stainless. Slot a tube in there matching the diameter with a welded a flange on one side, probably the outside so you can extend part of it to hold a latch mechanism. Screw the flange into the door and good to go more or less. Could stuff it with some insulation or make some kind of insulated cylinder to fill it with while it’s cooking to not loose heat.

I’ll do a sketch.

I’m really not a fan of rivets, especially on moving parts. One of my door hinges is already loose on day 2.

2 Likes

Send me the Fusion file and I will make one.

Looks perfect

2 Likes

Yeah I think it could work. Probably want a gasket on the door which could impact the hinge but aside from that I think it’s solid. I want to do one now. File incoming.

1 Like

Instead of a hinge you could do a twist lock plug so you can maintain the thick insulation of the door.

I’m working on it. Just got the SS 4 inch tube. I have been covered up. I will use the hinge like the first version. I also have the latch from McMaster-Carr.