Starting using 5 days ago. No real problems outside of operator error, but all of the sudden my torch would stop cutting through the metal then would blow out and stop. After investigating I found that my torch Z axis would start lifting away from the material then shut off. Please help. Thank you

Sticky IHS switch maybe getting triggered mid cut, raising it up.

Or

Bad Voltage measurement for THC because of Bad consumables or loose wiring.

Or

Incorrect nominal voltage entered in firecontrol. Enter correct nominal or switch to smart voltage.

Or

Incorrect cut used while generating toolpath. Too high.

Start checking these reasons out.

Thank you, these reasons all make since. Question’s:

- Smart voltage is turned on, but I am cutting 16ga which is states smart voltage on used for 14ga+, could this be the issue?

- Would an incorrect toolpath present itself halfway through a straight cut line, i.e. like a stripe of the American Flag for example?

Just trying to rule out / reign the possible obvious like settings. It has happened trying to cut the same file two separate times but in different places. 1st time halfway through the cut and the 2nd time 3/4. The second time, after some researching, I retry the cut from failed location with THC off and then once it got a little passed the area where the cut originally failed, I turned THC back on while cutting then it happened again just shy of completing the file.

I know this is a lot and hope it makes since. Thank you so very much for your input/expertise. I am truly appreciative.

is your Air keeping up to the plasma torch?

You should be fine

unlikely sounds like a air issue ?

can you post a picture of your consumables ?

did you pass your THC test?

which plasma are you using and how is the voltage hook up ? Raw or Divided ?

Have any wires or cable been moved?? My pro will do some wacky voodoo crap if my USB cable even swings close to one of the table legs.

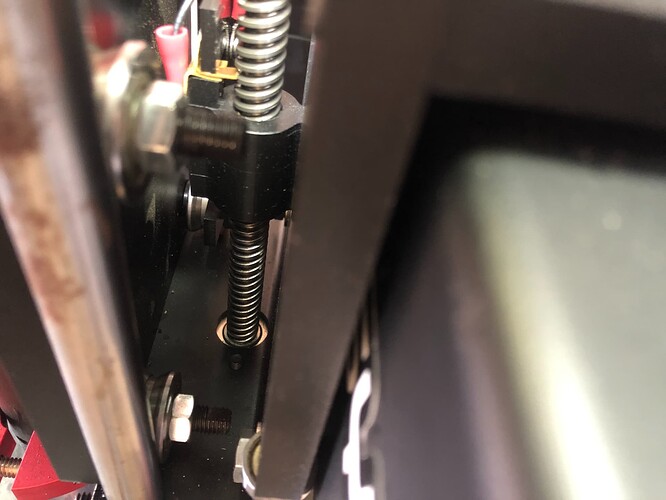

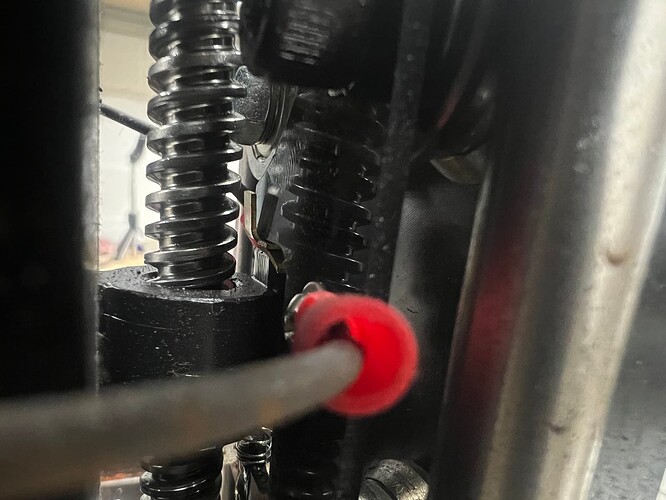

Well, I am trying a new cut after finding that the THC contact that is fixed to the Z Axis torch mount was protruding into the Z Axis lead screw. I could manually raise the Z Axis and lower with the tab staying in the threads of the lead screw. Focusing my attention first on the “Sticky IHS switch maybe getting triggered mid cut, raising it up” led me to check the Z Axis hardware first.

I am under the assumption that with the contact stuck in the lead screw thread is what is making the Z Axis climb messing with the voltage.

Processing: 35B5281F-1D51-430F-A390-9705565C3618.jpeg…Well, I am trying a new cut after finding that the THC contact that is fixed to the Z Axis torch mount was protruding into the Z Axis lead screw. I could manually raise the Z Axis and lower with the tab staying in the threads of the lead screw. Focusing my attention first on the “Sticky IHS switch maybe getting triggered mid cut, raising it up” led me to check the Z Axis hardware first.

I am under the assumption that with the contact stuck in the lead screw thread is what is making the Z Axis climb messing with the voltage.

@langmuir-reilly @langmuirsystems

@langmuir-aksel

Check out the OP’s pictures of the IHS contact

That’s not cool

Well, that was the problem no doubt, cut flawlessly on the same file I tried twice yesterday. Thank you guys for all of the help and suggestions.

Thank you for posting pictures of what you found. That brass piece that is contacting the Z-axis lead screw is very soft and malleable, and it should be bent upward such that it wraps around the plastic lifter switch plate. It sounds like you might have already done that, is the Z-axis working as expected now?

Hey everyone,

I’m running into a frustrating issue with my Crossfire XR where the Z-axis lifts out of the cut mid-process and ruins the part. I’ve gone through a bunch of troubleshooting steps, but I’m still stuck, so I’d really appreciate any help or insight you all might have.

Issue Summary:

- The torch cuts fine at first but eventually starts lifting out of the material and stops cutting through.

- The guard portion of the sword file cut perfectly, but the blade has failed in the same spot (3 attempts so far).

- Disabling height control after penetration didn’t fix the issue—Z still climbed out of the cut.

- I’ve created new files to rule out toolpath issues, but the same problem persists.

Troubleshooting Steps Taken So Far:

- Air supply checked – Compressor is keeping up with the plasma torch. Also no moisture in lines.

- No wire movement – I haven’t moved any cables since my last successful cut.

- THC test run – Test said my voltage was slightly low but still fine (Prime Weld 60).

- Raw voltage hookup confirmed – Everything is connected correctly, and I’ve reseated all connections.

- Consumables checked – Tip has about 50 penetrations on it. I don’t have spares right now, I need to get some ordered.

- Hardware inspected – No loose components, nothing visibly wrong with the Z-axis mechanics.

- The brass IHS contact issue that TXMEDIC had is not it.

I feel like I’ve tried everything in this thread and have gotten no where. Hopefully someone can point me in a direction to test.

I really appreciate any insight you guys can provide. Let me know if you need more information, pictures, or settings screenshots, and I’ll get them posted.

Thanks in advance!

You might take a look at this post from Langmuir:

Another thing to do is watch FireControl and see if the IHS light turns green just prior to it lifting. There could be a break in the wire that is separating exactly when the torch is in that area of the table. It would be interesting to rotate the cut 90 degrees and see if it still happens at the same, relative spot.

Otherwise I would say there is something going wrong in the THC. You said you tried cutting without IHS but did you try it without THC? I would try that.

Unplug and plug back in usb cable from computer end and table control box, try different usb cable. Try disabling limit switches, seems someone on forum had a limit switch shorting and causing Emi problems with torch?

In the last picture, make sure that the brass tab is not coming in contact with the Z axis lead screw. This same thing happened to me after having my XR for a while. The cut would start, then on long runs would the torch, after initial touch off and fire would just start climbing out of voltage range.

It was actually the limit switch tab I believe.

Click on my post and you will be able to see what I had posted back in 2022. Good luck sir.

This is not an XR table and there is definitely something not right with that IHS switch. Is the IHS light in Firecontrol green when this issue occurs?

Does the green light turn off/on when manually lifting the Z axis?

Also, when raising the Z axis up/down make sure the contact switch looks like it is making contact and releasing as it should, from a mechanical view and not getting hung up anywhere. The following is from an older post I found regarding the “Green Light” comms.

"If the light is on all the time, a wire is unhooked or the contacts are loose in the Z axis.

Check the two wires that go to the IHS switch and make sure they are firmly plugged into the wires connected to the switch.

You can do a search on the forum for IHS switch to find pictures other people have posted.

The have been a several instances of recent Z axis assemblies that have loose or improperly installed contacts from the start."