When I go up in material size and change tips it will not complete the program. Hypertherm85. I can cut 11 ga with the fine tip no problem. When I go up to 3/16 material with the 85 amp tip it would stop about 75% around a 3/4” hole. It will dry run the program all day long. I even created a 3” x 3” square plate blank with no holes or anything and it still stopped approximately 75% around the plate. It will also leave the torch firing when it stops. I have to hit the kill switch to get it to stop. I have checked air pressure, all cables, restarted machine several times. Again, I can change tips and go back to the 11 ga material and it will run that program with no issues. Any suggestions? TIA

So you are saying the movement of the torch stops???

I had that happen with EMI. Torch stopped moving but continued to burn and FireControl continued thru the path even though the table was no longer responding.

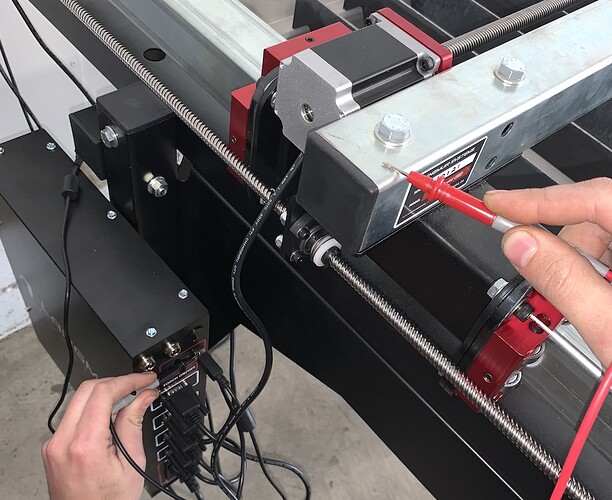

Perhaps when you hit that higher amperage, something is happening adversely. Try moving the cables around, remove coils of cables. The cables that are most problematic: USB cable from computer, work lead, torch lead and THC cable from VIM box to the enclosure.

Can you share a photo of your setup?

It seems that the consumables are not up to specification. EMI would occur whenever the torch is firing. My question is, where are they sourced from? Hopefully, it’s not from Plasmadyne.

It is not the torch or the plasma cutter if it works with the 11ga consumables.

Home sick today, so I will be blowing up the forum to keep from going batshit crazy.

Define will not complete please.

Stops following the cut path and movement stops but torch is still firing…

Torch goes out, but keeps following cut path…

Everything stops, error on fire control screen…

Post the first 20 lines of your Gcode.

Open the file as a text document, copy, paste.

Machine and consumables are brand new. First time to fire the machine was Saturday. Tech support ask me to try another loop in the usb cable and to also find out what the torch voltage was reading while it was firiing. 127.6 V which is between the 90-150 that he told me. I’m going to try a smaller tip (45 or 65) and a new usb cable and see if that helps.

-The torch stops following the cut path but the torch continues to fire.

-Once that happens it freezes the Fire Control software and I have to shut everything down and start over.

-no errors on the control screen

-I(v1.6-af)

G90 G94

G17

G20

H0

(2D Profile1)

G0 X0.9499 Y-0.1

G92 Z0.

G38.2 Z-5. F100.

G38.4 Z0.5 F20.

G92 Z0.

G0 Z0.04 (IHS Springback + Backlash)

G92 Z0.

G0 Z0.15 (Pierce Height)

M3

G4 P0.25

G0 Z0.125 (Cut Height)

H1

G3 X0.8499 Y0. I-0.1 J0. F185.

G1 X-1.25 F185.

G2 X-1.54 Y0.29 I0. J0.29

G1 Y2.79

G2 X-1.25 Y3.08 I0.29 J0.

G1 X1.25

G2 X1.54 Y2.79 I0. J-0.29

G1 Y0.29

G2 X1.25 Y0. I-0.29 J0.

G1 X0.8499

H0

M5

G0 Z0.5

M30

(PS185)

Thats correct. The movement of the torch stops. I currently only have a fine cut and 85A tip. I am going to purchase a 45A and 65A and see if either of those will work.

Happens to me when I interrupt a cut sometimes, or a weird save. Try restarting you computer and run again.

Make sure the USB cable is not running parallel with either the work clamp or torch lead, and that neither the work clamp cable or torch lead extra is coiled up.

Your pierce delay needs to be increased. Set it at 0.7 seconds and see how it does.

…but that does not explain why it is cutting and then stops. I am still thinking something else is going on.

My work clamp cable is coiled up over by the plasma machine but I will undo that and try for sure.

Is your machine a SYNC machine? Because you are way off with your cut height as well. It is way too high if you don’t have a SYNC machine.

These two numbers are creating a cut height of 0.165 inches!!!

You should be closer to 0.06 inches.

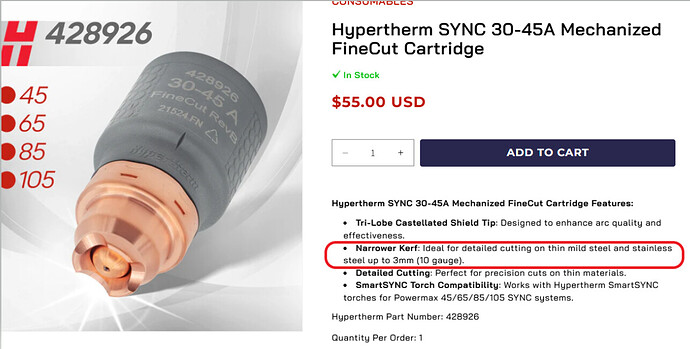

And if you are using the Hypertherm 85 SYNC machine with Fine-cut, it is only recommended up to 10 gauge. The fine-cut on the Hypertherm Non-SYNC using non-sync fine-cut consumables have been known to do okay with up to 3/16" metal.

Sync cut height is IIRC .12"

I know. He is using the sync cut chart but did not say it was a sync machine. The SYNC fine-cut specifically says that it is ideal for thin metal. I suspect he has a SYNC machine.

It is a powermax85 SYNC machine. The cut height is set the height in the chart that came with the machine. I can adjust the springback and backlash if needed.

I only have this tip(fine cut tip above) and the 85A. I am going to try and find a 45A and 65A local and try and see if that will help as well.

Exact same thing happen to me. Drove me nuts. Works perfect now. If your using Sheetcam watch this video from ( Premier Plasma ) and make and Inside layer and outside layer. And keep the Fire Control Driver… Problem Solved. Hope this helps… https://www.youtube.com/watch?v=aHRTZOGh3yA