the geometry says it was 144 lines

Can you send the G code file to support@langmuirsystems.com?

Also please let them know at which point in the program the machine pauses.

ok thx will do that hope I can cut soon

I was going though the G code start and it did stop at 504

is that why it stop I need to buy the license

Yes, Mach3 will stop at 500 lines without the license.

ok thx for responding I’ll see what I can do

oh then it will proceed to cut all of my project’s

Yes, with the license there is no restriction on the number of lines.

ok got it, thought it will at least get 1 cut just to see how it will cut, ok thx

Mine did this last night at the coupling on the y motor… thinking of drilling into the rod and using a longer dog, or even right through it for 100% engagement.

yea I was going to do same thing but the JB weld lock tight is holding great

did not want to lose my warranty, my table still has 7-8 months left

I wrote to LG and they send me another coupling with the set screws

@jimt

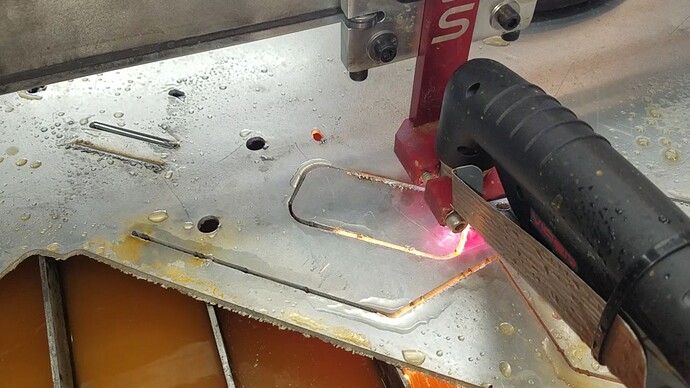

Is this what yours was doing here when it went wacko? Look at the start stop marks along my cut lines… what did you do to fix it?

That’s not the same issue that Jim has experienced. Yours appears to be some type of mechanical issue on either X or the Y axis. I reccommend disconnecting the Y axis lead nut and cycling the carriage by hand to see if you feel anything. The spacing between the divots looks like it happens once per rev of the bearings.

@langmuir-daniel seems to be fine while doing a dry run

@langmuir-daniel think I found my problem. My x axis stepper motor is loose on the side of the gantry. Feels like the bottom bolt is not attached and the top is barely attached. Have a video but I cannot post it can I email it to you?

After trying all electrical componets, replacing all bearings. Still have that problem on curves. Daniel has been awsome trying to help me figure it out. After a basic test we believe the leadscrews and or lead nuts are somehow failing. Soon as i receive them and install them we will know for sure, so hopefully this is the cure.

I guess i forgot to post my findings here. After changing leadscrews and lead nuts it continues the jerky curve cuts. Daniel sent me new x and Y rails and the Yrail cured the problem. Not knowing exactly why, Im guessing it was a combination of a couple bearings getting worn out and somehow wearing the Y tube . Daniel was great in sending me pretty much everything but the table frame to work this problem out. Thank you again Daniel. LS has given me the best customer service I have ever received. And please thank those working behind the scenes who was part of getting me up and going.

I love it when I buy a product and the company stands behind it. A few years ago I bought a RecTec Pellet grill. They are the same way, I can call with a problem (which they have been few) and they have the parts out the door that day.

Yeah, this is what I think is up… the bearings may make things stiffer and noisy but all that erratic stuff - I think its motor drive screw issue…

Glad you got it worked out.