i have a crossfire second gen with XL kit on it and a Cut60 from primeweld, im having issues with machine settings and feeding rate and other user error cuts, i would appriciate someones help/mentorship i really want to step up my game however theres not much out there about this set up, everyone i run into is either using mach3 and sheetcam, i chose fusion and got the hang of it. thanks in advance

welcome back…been a while…

so a 2x2 crossfire XL

Primeweld cut 60

Running FireControl

what design software are you using?

what post processor are you using?

what sort of problems are you running into…??

do you have some pictures?

do you have dry air?

do you have filtration on your air?

more information will be able to allow us to help you

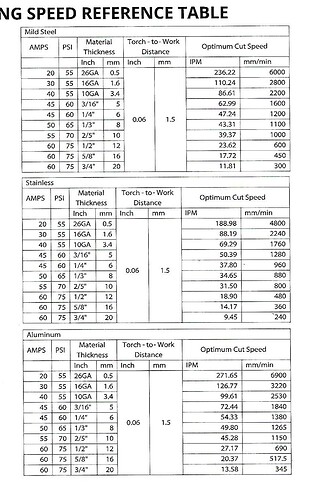

Im using fusion 360 to design and everything there I got the hang of, when it comes to for instance I’m trying to cut my logo out of 1/8 inch aluminum the lines are bad and seems like too much travel speed and the cuts aren’t defined as you would expect, I always read people saying I set up IPM, amps and psi but I legit don’t know where I can find a chart for cut60

the cut chart is in the manual towards the back.

The PrimeWeld CUT60 chart is pretty darned spot on!

Unfortunately as every man

i threw that away and can’t seem to find a pdf, if anyone can upload a pic or refer me to where I can get a digital copy that would be bad ass

i threw that away and can’t seem to find a pdf, if anyone can upload a pic or refer me to where I can get a digital copy that would be bad ass

Thank you so much!! Yes that’s exactly it and from what I can tell I was really off in the settings

for the most part, it’s pretty accurate. Start with those and adjust to your liking.

The Cut60 manual in pdf form is under the “File” menu at the top of PrimeWeld Facebook forum.

If it’s still cutting way off the cut chart, check to see if your swirl ring is the correct direction.

I used the chart provided here (thank you so much by the way) and the cut profile is still crooked, holes come out a bit slanted on the cut isn’t 90 degrees, I’m using the hang held torch, I recently cut some basic square tabs and one line came out really good (y axis) and the rest seem to have issues with a lot of dross and a bit shaky, if anyone here is willing to help me out I’d highly appreciate a small crash course on this machine, I love it I just want to work out through the bugs

This plasma cutter has since been put on Langmuirs no no list. Are you all experiencing electrical interference issues?

it was put there as there have been numerous issues with electrical interference issues between it and the electronics…

some people have zero issues…others…oh boy…