Being one of the lucky batch 1 owners of the CrossFire, I figured I would put out a review for those of you who haven’t gotten yours just yet or are on the fence for buying one.

I bought this machine to expand my list of tools and start a small business doing light fabrication work and plasma cutting. I have been fascinated with CNC since college, where I learned how to program, and when I found this machine and saw the cost, I had to go for it. I got my machine last Friday so I have only had it 5 whole days, but it’s been an awesome experience thus far.

The whole unit arrives in one box- which is super nice not having to cut open a bunch of boxes. Everything is packaged well and protects all the components. Assembly is super easy thanks to the How-To videos the Langmuir guys have put out. I just threw on the videos in the shop and followed along. Alignment was the only thing that took a few tries to really get right, more than likely that was me being a perfectionist more than anything else.

Once I got the machine assembled connecting the Razorweld plasma cutter was again super simple thanks to the how-to on the Langmuir website. Honestly nothing was difficult because all of the questions one would have, are already thought about and documented.

The machine has been thoroughly thought out and it shows. From assembly to cutting my first test piece on a piece of scrap was 3-4hrs. From that I was able to model, program, and cut the laptop support piece. From cutting on the CrossFire to powder coat took maybe 45 minutes. It’s that simple.

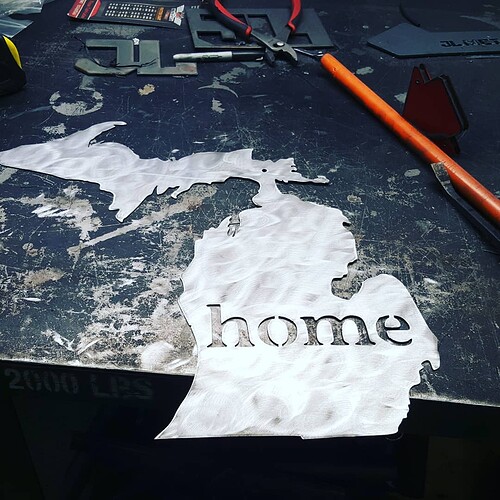

After a trip to the metal supply shop and my water table arriving (which again was super simple to install) I got to cut my first products that I’ll use as advertisement for my company and selling.

The Razorweld 45 cuts really well and running the CrossFire utilizing Mach-3 is rather intuitive, even though I’ve been away from CNC for years it was no problem jumping back in. Plus, if I had ANY questions the Langmuir videos are an excellent resource to reference.

If you’re on the fence about buying this unit, I would 100% recommend it. Super easy to use, great resources for learning, affordable, excellent for someone who is getting started in the hobby/business.

John

JL Metalworks

Instagram @JLmetalworks10

Facebook @JLmetalworks