Hi there.

we’ve had our crossfire pro for about 2 weeks and are going through the “learning curve” of getting things to work.

when we do the “health check” for THC we get 0 volts throughout the whole process… and then the first completed screen says your’ within range… COOL!!

then the 3 torch on and off buttons…

then we get a FAIL because of no voltage…

we have been through the “flow chart” a dozen times or so… we’ve taken the THC out of the mix to try and cut anything without the torch snuffing on the first cut.

we did find that while running a program (cut) and the compressor came on… we would snuff out the torch. so we changed the source to the plasma cutter… that remedied that issue.

we’ve isolated the control box by removing it and keeping it away from the table…we have removed the charger from the laptop, we’ve measured the resistance.

realistically I was wondering if I could trouble someone to take a video of they’re machine going through the THC health check so I can see the readings your getting.

what cutter are you using? and is the torch tip hitting the material when it first initializes? when you press START, it should go down and hit once then comeback up about and inch then fire and start cutting.

Hi there…

we are using a hypertherm powermax 900 with duramax retrofit hand torch.

the tip does it’s routine of touch off and then raises to fire.

I’m looking for input on the THC health check and would like to see what voltages people are getting…

we… are getting 0V…

we have had some successful cuts… in thicker plate…

Your is polarity is okay.?

“Ground clamp” work clamp positive red

Electrode or torch negative black

I assume you went the raw voltage route.

You need to be tracing the voltage back to the plasma cutter and determining where the ~disconnect is. The THC Troubleshooting Guide should have you testing voltages with a multimeter.

Are you getting 0V straight out of the plasma cutter? at the VIM? at the electronics port? at the THC board?

Hi there. Yes to both questions…

and for the plasma cutter voltage we had 86V, then from the VIM we had .76V. So the 73:1 ratio of the VIM was within spec.

And yes to the Raw voltage connection…

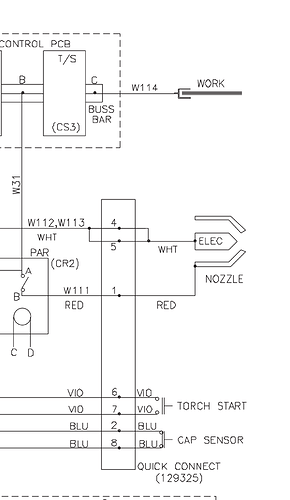

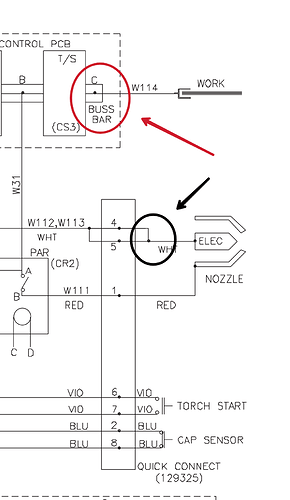

https://www.hypertherm.com/Download?fileId=HYP104623&zip=False

I’ll leave the link to the manual for any future people coming upon this topic.

Whereabouts based on this wiring diagram for the manual did you make your connections?

Something like this?

I’m just making sure it’s not hooked to the nozzle where it may show voltage briefly.

Hi there… thank you for responding.

Im away from the shop now, but yes… thats what my connection looked like. Red to work clamp and black to electrode.

I’ll try to confirm to be absolutely sure tomorrow. But I’m pretty sure its the electrode and not the nozzle. I had a co-worker check it as well when we first started the troubleshooting.

Thanks again

Did you clamp your work piece with ground clamp? I forget this sometimes, also sometimes have it too far away from cut area through spindly cut out sheet.

Hi there. Yes we did clamp the work pc. And the material was only 12” wide so the furthest distance from the torch was 16” or so. We ground a spot for better contact as well.

Thanks for the suggestion though. It’s often the simplest things I forget…