More like when they fired the final version and burned through the target, the backstop, the wall, the statue, the tree, the billboard…

How about dull side ceramic tiles laid in the tray , yes it can cut it but it takes longer than steel.

Nice to see this thread and video. I posted a question on Travis Mitchell’s forum a few weeks back asking if anyone has done what you have done. I’m thinking of converting a Crossfire Pro into a 2KW laser system. I guess I’m not crazy after all.

Or you’re as crazy as @holla2040 !!! ![]()

![]()

![]()

Keep your fire extinguisher handy.

We did buy a BM110

In case we wanted to swap out the gun.

nice… looking forward to this upgrade…

Right now, this swap is not in immediate future. We may buy a used fiber source for it.

Craig, I just took a roadtrip to a local CNC shop to have a piece of 11g polished stainless steel cut on a laser table. This guy has a large houseboat at the marina.

This Laser table is a 12000w Trumpf $900k

Very impressive. It will cut 1.250 stainless like butter.

Here is a crummy video I took through the window.

First it plots the sheet position

Then changes the optical lens to what its cutting.

Then it low power cuts the vinyl cover

Then cuts the sheet.

12kW is killer big and fun to watch!

Hoping I can add here in the next few weeks.

My friend just placed an order for a 5 x 10 laser table, and he’s got his STV table up for sale.

Going to be fun swinging by and seeing it run in person.

What shade is required to protect one’s eyes while running laser?

I wear OD6 supplied by our laser supplier. It’s best to contact your supplier and get their recommendation.

Well it looks like x tool has now put together that plug and play version of these mini laser tables.

I wonder what it’s expected material thicknesses are for cutting

Hopefully Langmuir is up to the same thing in the background.

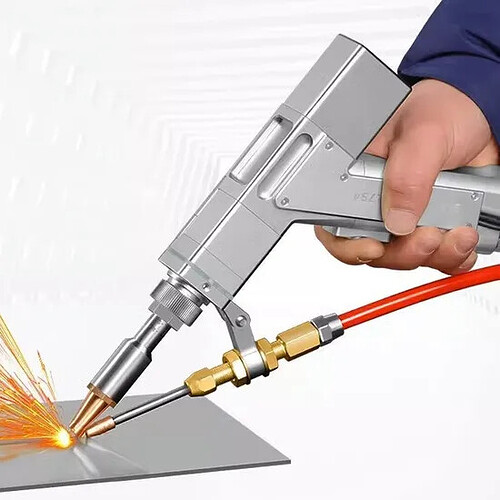

Looks like xtool has a better wire feeder attachment to the gun. Most of these laser welders have a mickey-mouse setup.

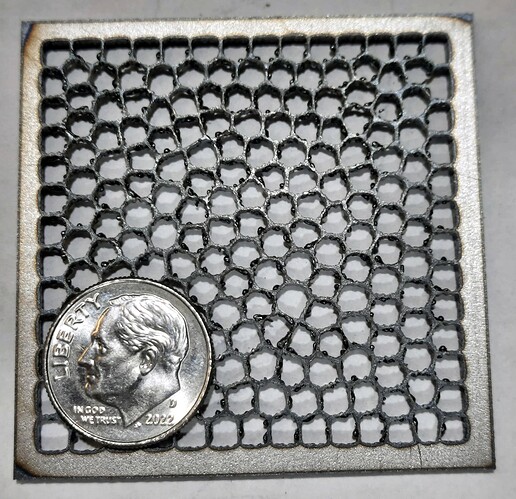

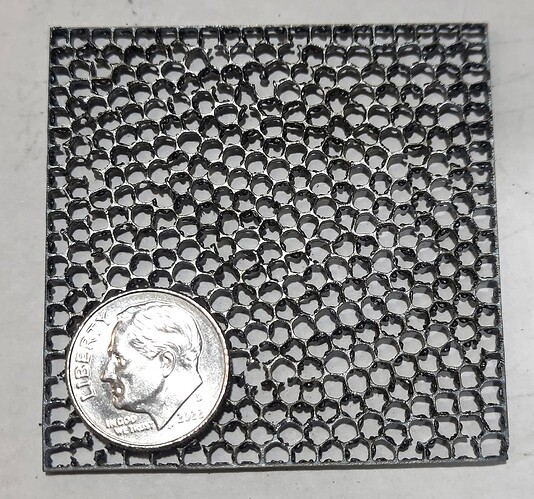

Friday Laser Fun.

18ga CRS 50x50mm voronoi coupon

40IPM 400W 200 cut outs 0.5mm spacing

20IPM 300W 400 cut outs 0.4mm spacing

Quite impressive, with these wafer thin bridges removing back side dross would likely tear the piece apart. I believe the second coupon is a little past the Crossfire Fire’s mechanical repeatability tolerance. Stock flex poses a serious issue with some of the bridges being blown out.

Fascinating. You are, indeed, a pioneer. Great stuff!

Very cool stuff. That is impressive how well you got it to cut, by just playing around with simple stuff.

Thanks for posting, now I want to swap mine!

![[Official Teaser] xTool MetalFab Laser Welder and CNC Cutter - Metalworking Made Simple!](https://img.youtube.com/vi/FfQUxRr2zjM/maxresdefault.jpg)