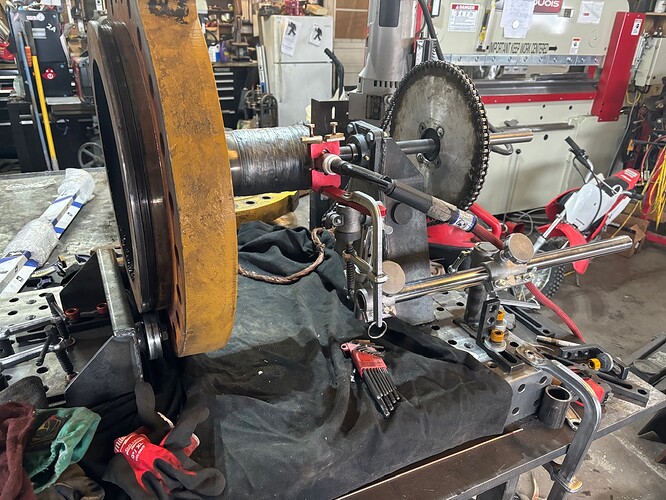

I Used my pro to make a rotary position setup for a job. Had two build ups to do 5” long on a 4” dia shaft. Customer supplied wps which was tig weld process, 4130 filler, 400deg preheat. Min of 1/4” build up.

I made my set up to attach mostly to my Arc flat so I did not have to build a base and can store and set up again as this may be a repeat job a couple times a year. I even used my old hand torch mount off the pro to hold my tig torch.

Roughly 18hrs of weld time. Fun project over all.

I need to get my arc flat on some legs though. I wish LS had made the tables 5/8 thick so the strong hand ball locks worked seamlessly but a few cheap washers gets the job done.

2 Likes

nice work! that is my daily grind. we mig all our fits. what does that spindle fit? motor grader?

1 Like

Not sure the model but I was told strut tower on cat haul truck. I was surprised what they wanted for a weld procedure but more than happy to oblige. Next time I’ll get .030 mig wire and automate the feed process too so I can smooth out that weld.

most of my repairs are for dozers. our company does still outsource a lot of our repair work.

most cases we undercut .08 to .100 tho then weld with a .045 and machine to size. that wasn’t a part i was familiar with i know they are in the warehouse never had one through our shop.

A++ nice job.

Thank you! I appreciate the kind words. The machine shop had this undercut some where around .150. It was sure nice work during the cold snap we just had. I do lots if mobile welding so shop jobs are ideal this time of year.

2 Likes