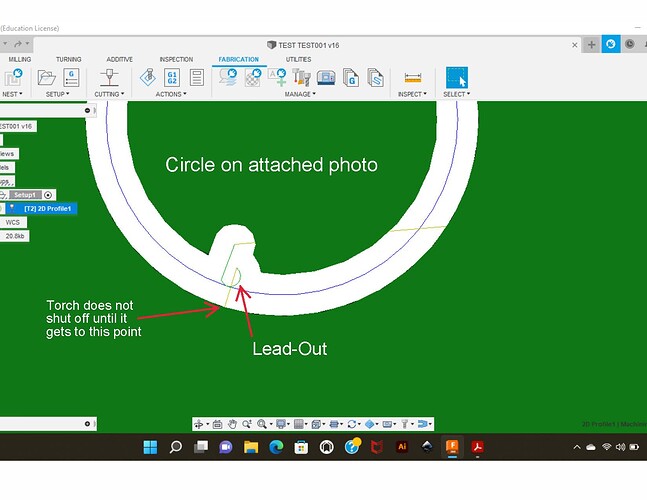

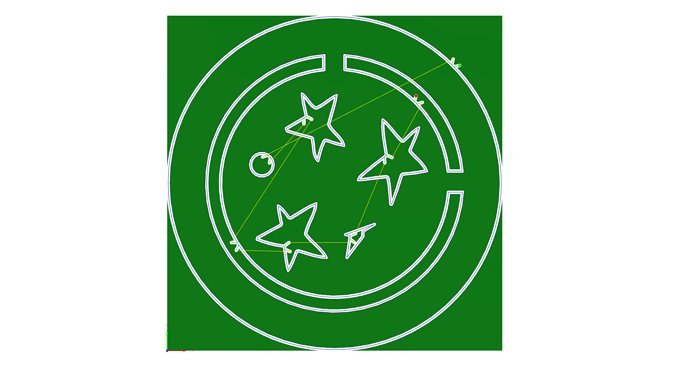

I am using Crossfire / HF Titanium 45 / Fusion 360 set-up and my torch is not shutting off before leaving divot (see attached photo and Fusion 360 screen shot of tool path of circle)

Has anyone had this problem? If so is there a setting in Fusion 360 or Fire Control that can help turn the torch off at end of Lead-Out setting?

can you post your F3D.

that is strange looking lead out.

The titanium 45 maybe a little slow to shut down at the end of a cut. I would provide more lead out to minimize the mark from the “off” delay.

Yea its 160 deg. lead-out sweep angle. I tried everything from 30 deg. to this 160 deg. and nothing worked.

TEST TEST001 v16.f3d (1.4 MB)

The problem with larger lead-out radius and distance is i lose my ability to do the smaller detailed cuts.

This problem seems specific to the Titanium plasma cutter, because this is the 4th person using that cutter that has had the same issue.

Sheetcam allows you to add a pause at the end of the cut. That would allow the torch time to shut off before moving to the next loop.

I sent one of my Sheetcam files, with a .5 second pause after each cut, to one of the people having this problem and it worked fine.

Somewhere in the forum is a post where someone wrote a script that will add these pauses to a Fusion G-code file.

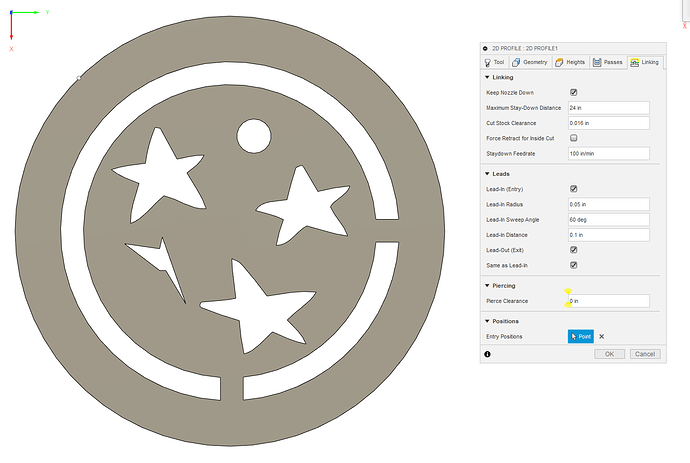

I adjust some parameters and it seems to fit on this design

check out the F3D I attached

TEST TEST001 v16.f3d (1.4 MB)

bigger lead in and out will help your issues hugely

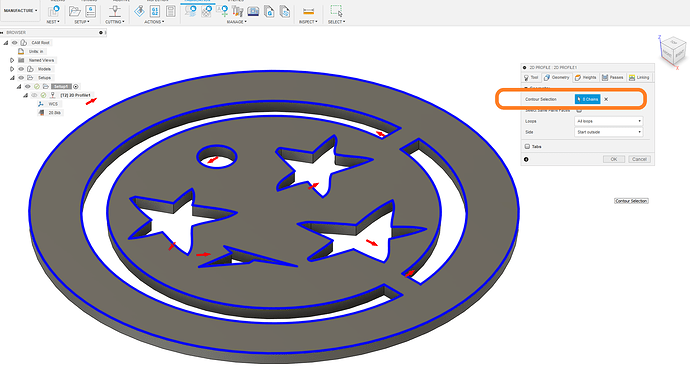

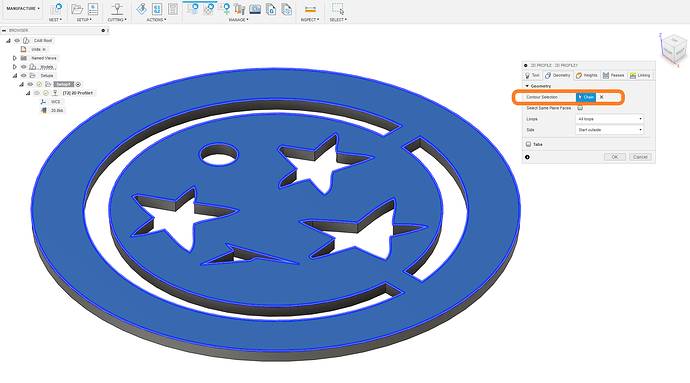

When selecting geometry in the 2D profile menu. It is quick to select the whole face instead of the individual contours.

Here you had to select all 8 individual contours

Or you could select the face which selects everything

TinWhisperer I ran the set-up you sent and still have the issue as you can see in the photo. It looks like I need to try using SheetCam for post files or change plasma machines.

Can you tell me what machine you are using?

You have no z-axis in your machine?

I noticed you had the keep nozzle down function checked.

I’m going to try another version of parameters to deal with your torch turning off slow.

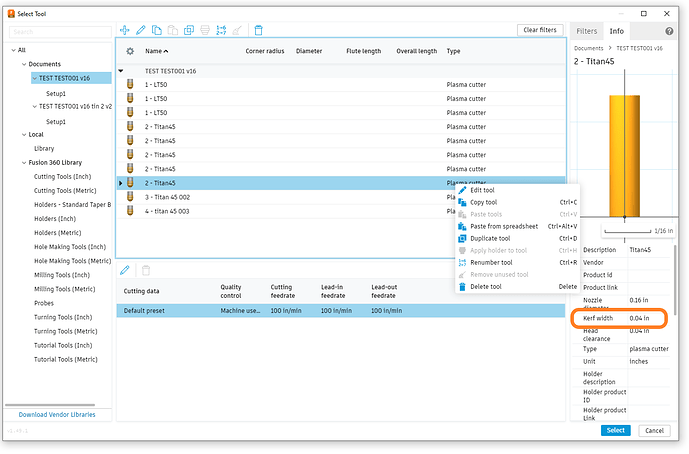

Do you think realistically that torch is giving you a kerf width of .04 like showing in your tool setup

My kerf is actually .395

You are correct I do not have the Z-axis on the machine. May add later.

we should change that to the .055

This maybe the underlying issue

the kerf width for that tool was set to .04"

try this new f3d

TEST TEST001 v16 tin 2 v2.f3d (1.4 MB)

Can you tell me what plasma cutter works with Fustion 360 progam without these issues?

I’ve tried multiple settings and it just will not go away. Not really ready to learn SheetCam

Personally I’ve run a

Hypertherm PowerMax 85 (current set up)

Everlast 60s

Miller Spectrum 375

and I bought and soon will have a Hypertherm 45XP

Fusion 360 worked with these units.

Maybe you have something wrong with your plasma cutter and its shutting off late.

@mechanic416 George, any known problems with the HF Titanium 45 shuting down slowly?

I have been using the titanium 45 for over two years now on my crossfire pro trouble free. Using the plasmadyn x45 machine torch, no misfires or shutting off. How far away is your cutter from table control box?

There is no reason for the Titanium 45 shutting down slowly.

The cutter is 3 feet from the crossfire control box.

I bought a Prime Weld Cut 60 got it all hooked up. I ran the same g-code programs and the divots are gone.

This machine works GREAT I would strongly recommend it.

Did anyone figure this out? Mine does the same even with fireshare files right to fire control

Welcome to the forum.

A word of advice, any delusion that a ‘cut ready’ file is, in fact, cut ready is a delusion. Assume you need to, at least, examine it to confirm it’s cut ready for YOUR system and then, once you find out it isn’t make the appropriate adjustments…