So I can get my table dialed in so that there is almost no visible dross in straight lines or larger curves but it will not keep speed in the tighter curves it seems to slow way down and it produces quite a bit of dross. I know it’s going to spend more time in an area if it’s curving around but it definitely isn’t keeping the material ipm speed up. Maybe it’s not possible?? Thoughts? Others’ experiences???

Cutting 3/16 mild steel at 45 amps

Standard issue if there are a lot of points in your circle or arch or design for that matter. The machine has an acceleration rate of 40 ipm. So at each point it slows down then speeds back up at a rate of 40 ipm no matter your feedrate or settings. This is why your design needs to be as streamlined as possible. It will increase your “blended speed” the better it is. If you notice it’s moving a lot slow then you think it should just turn the amps down during that section of cut and back up as it gets faster. Now you can only do this on infinitely adjustable knobs. Never do this with “click” knobs.

The other way to help this is by having bigger, stronger, and faster motors on you x and y axis. Then you could increase your acceleration rate.

This makes perfect sense. Thank you. I was unaware of the acceleration rate. 40ipm seems about right. I’m running 122ipm and it slows to a crawl when it’s cutting around the small details. Is there a setting that eliminates short moves and “smooths” the design?

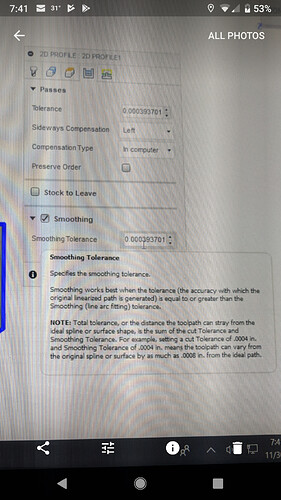

I think it’s the linking tab when setting up the cut profile. It’s underneath where you set it to be in computer versus in control. There is a box to check called smoothing and that will help with smoothing out the design. Other than that you’ll need to draw your part with as minimal points as possible

+1 What Burgs04 said. This is why it’s impossible to get dross free on 14g because it’s mostly art or detailed work. If it was all straight lines then it’s pretty easy to get minimal or no dross

So on something with lots of curves that you know its going to run slow on would it be advisable to run a lower amperage and lower feed rate as to minimize the change in feed around the curves?

Correct (plus more characters)