so was wondering, is there a way Langmuir could add downloadable “machines” with all the specs already set up for use in fusion 360? I’ve been looking at the cut charts, but having to input them every time i am cutting a new piece does open room for mistakes and makes just starting out more difficult. also, if i change from cutting 14ga sheet steel to cutting 1/4"plate for the same shape, then i have to make sure to input all the settings all over again.

what i mean is this:

is there a way they could call a downloadable machine “Razorweld 45 for 14ga to10ga steel”? there are so many settings in the “machine” part of Fusion 360 that having a pre-set up “machine” of choice for cutting certain range of guages of steel (they could be grouped in the thickness range 14ga to 10 ga, then 8ga to 3/16", etc.)… i am unsure of all the necessary settings for each of the screens for each “machine” setup i’m trying to set up. any help is greatly appreciated.

I’m not so certain that having “machines” is the best answer. Personally, I define individual tools for each thickness we cut. Then its’s as simple as choosing the tool for the material. Minor tweaks, such as knowing what pierce delay is for each, but that can also be entered into the tool notes.

Here’s ours for a RazorWeld 45 - 18ga thru 3/8"

RW45.zip (1.9 KB)

thank you very much. how do i import/download that into fusion?

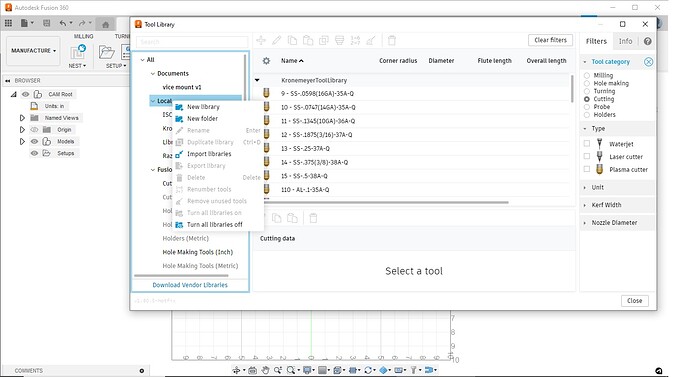

From the Manufacture space, select Tool Library from the Manage tab. Right click the Local tab and select Import Libraries as shown in the pic. (You’ll need to unzip the archive 1st.)

welcome to the forum…glad to have you here…

although the idea of premade/loadable tools for plasma cutting would make things easier…it really does not work and then puts the blame on Langmuir if they do not work…and they won’t work the same for everybody.

so I was given parameters for my Plasma 3 years ago…and within the 1st few weeks I realized they were not that great for my setup…why because eveyone has variables when cutting.

- altitude of where you live

- temperature and humidity where you live

- the quality (dryness) of the air you supply your plasma…wet or damp air affects cuts

- the stability of the air to your plasma…some people have volume/scfm issues and get poor cuts from it

- the power in your shop…is it being starved or dropping below optimal requirements…

all these factors affect the parameters for cutting…getting back to paramters from 3 years ago…I have greatly changed my air systems and power supply and it has made my cutting much cleaner and more controlable…

so one persons settings will not work for another…

you will need to learn to tweak and play with your paramters to suit the conditions you deal with.