Replaced my tip and electrode after a lot of learning and practice, thinking I had things dialed it. But then didn’t last long at all. After a few nice pieces the tip plugged up and the electrode didn’t look real good, replaced just the tip and it didn’t make it through another piece.

Wonder if it’s my cutter settings or perhaps my cutting speed? Was 1/8 steel at 65 ipm. Thinking it’s blowback plugging my tip. Perhaps a longer lead in time? Just so many setttings…

Thanks!

How clean is your air going to the plasma, dirty air and moisture will kill your consumables. I run a Pressure Regulator & Water/Oil Trap Separator, 60’ copper condenser tubes with drip legs and then a Motorguard M-26 Compressed Air filter right at the plasma cutter inlet and consumables last a lot longer.

1 Like

Very good point on the air supply. Just a small amount of moisture will instantly kill your tips. It’s not your lead-ins or blow back or speed. Make sure you don’t have any damage to the consumables stack above the nozzle and tip. If there’s a cracked swirl ring or plugged air holes, the heat is going to nuke your tips quickly

1 Like

What size tips are you using And what amperage

I’ve got a 45xp hypertherm and I run it at 45 amps. They don’t list sizes. There’s a standard cut, fine cut and a gouging. I’ve been running the standard tips and I’ve cut around 30 signs out of 14 gauge that are roughly 10x20" and my consumables still look very good.

Yeah, I don’t understand whats wrong here. I’m using the .08 tips running 35 and 45 amps. I also have a water separator, not really a dryer. But I live in northern Nevada (desert). I will check the entire nozzle for damage tomorrow.

Thanks

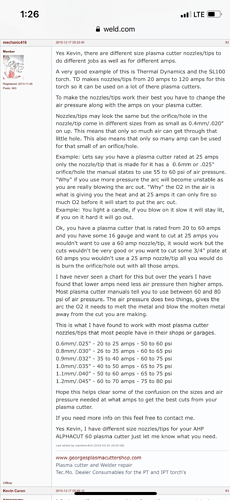

The .08 tips aren’t designed for that much amperage, that’s why they are not lasting. You need 1.0mm tips. Here is a good reference for you

1 Like