Hello, looking for compressor advice. Size, brand etc…

Welcome to the forum!

If you use the search tool, (Magnifying Glass in upper right corner, you will find a TON of info on this subject. The two factors are generally what Plasma Cutter you plan to use and the type of work you’re planning on doing. Detailed designs on thin metal or Large designs on thick metal.

The one thing you will hear constantly is that the air, supplied by the compressor needs to be DRY!!! Very Dry. If there is any moisture in the air your cuts will be poor and your Plasma Cutter consumables won’t last long.

Thank you!

hey Jay…welcome…

so as Tom stated your plasma cutter requirements dictate the basics of compressor size…but do not think a small compressor meeting the demands is good…you need to consider a compressor creates hot air and hot air carries moisture…and moisture is the devil to plasma…even super huge compressors deal with moisture…

so size your compressor based on your expected run times…cooling and condensing requirements…and budget.

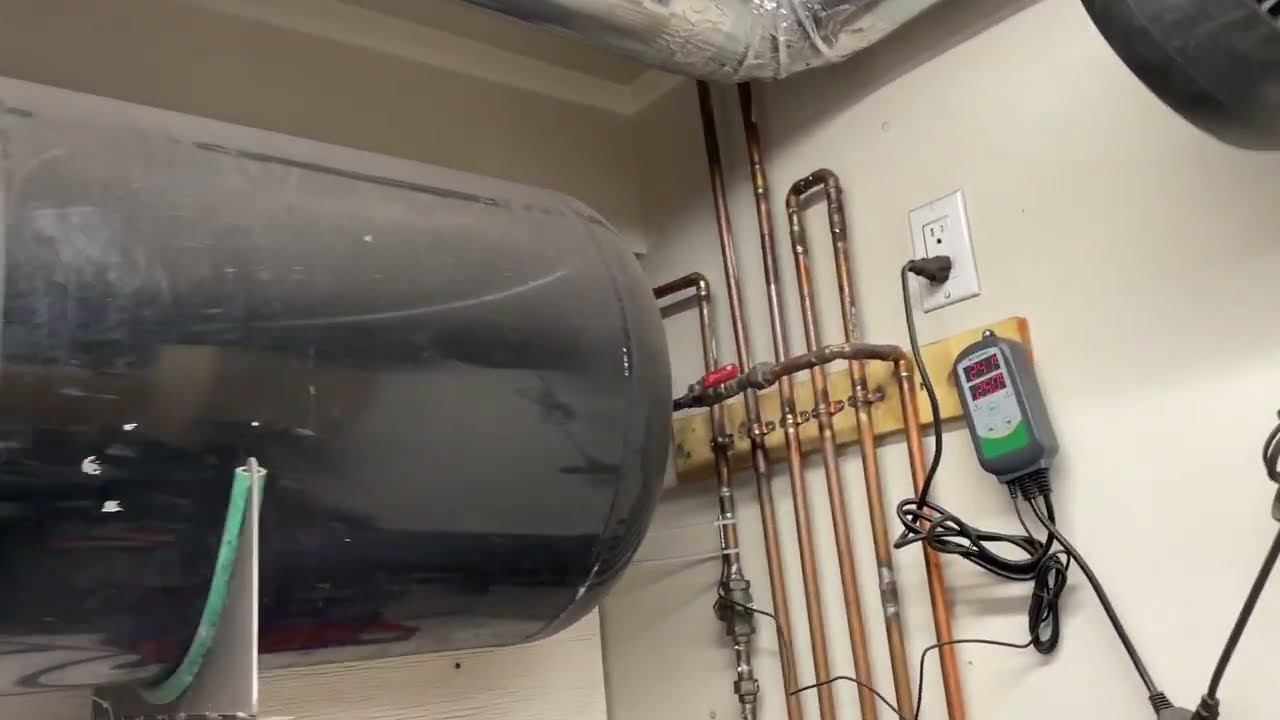

Here is my system for some basic ideas…this was something in the works for a couple of years…but it made a huge difference in my air quality and final cut quality.

Here is our system. 80 gallon compressor with Baldor commercial (low rpm, quiet)

motor. We built a forced air after-cooler between pump and tank…water/coalescing filters downstream pull out water and oil before the Atlas refrigerant dryer. Dry air then hits the tank. We periodically open the drain valve on the tank…nada. When we feed the shop air lines we first run through another set of filters then a 2 quart desiccant which lasts a while since we’ve already taken nearly all the water out.

First thing you need to know when looking for a compressor is what will it be providing air for?

Just your plasma table? will you be adding other equipment that needs air?

Some equipment requires lots of air like media blasting.

I have a compressor for other things but it mostly collects dust. I will only be using for a crossfire 2X2 garage welder guy stuff once a week. I was looking at this: https://www.northerntool.com/products/quincy-single-stage-portable-electric-air-compressor-2-hp-24-gallon-vertical-7-4-cfm-model-q12124vp-105043

Impressive, I am slightly less capacity than that. Thank you!

Very nice and looks efficient.

Your point about hot air carrying more moisture is important. An after-cooler won’t lower the dew point in your tank. But…if your pump is running continuously when the plasma cutter is operating, the after-cooler is removing most of the moisture from the hot, saturated air. If you run Pex like I do, keeping heat out is also important. Agree with your take on this.