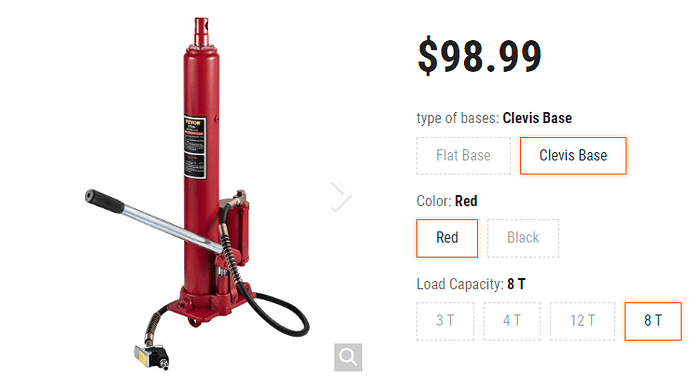

you can probably get that ram directly from www.Vevor.com and cut out the middle man.

I like the 12v idea…put a battery on the stand and connect the actuator to that…no hoses to run around the shop or to trip over…

Agreed. Minimizing hoses and extension cords certainly helps when rolling things around the work area.

just adding my experience with these jacks, long ram or otherwise, especially the cheaper ones… they pretty much universally have seals that go bad relatively quickly or it seems like either get a piece of grit in the seal or the surface finish on the hydraulic ram itself (the bare metal part that probably should be chrome like on equipment cylinders) is so rough it does the job of grit on the seals . i’ve gone thru several of the HF long ram air over hydraulics on my tube bender and engine cherry picker, and multiple different 20 ton jacks for lifting boats and stuff… not a single one has lasted more than a few years no matter how well i took care of it. I think i’m going to buy a better brand from now on, but even thats no guarantee.

Anyway, what i end up using most now for lifting stuff around the shop is the gantry i built for getting engines into and out of boats with a chain hoist and beam trolley, and its got three 600lb cap polyurethane wheel casters on each side. and after thinking about other’s situations here using pickers with smaller shops i think even if i had a lower shop ceiling building a smaller gantry still makes more sense a lot of the time vs using the cheap engine pickers, almost the same footprint just possibly more interference with fixed things rolling it around… possibly safer and more versatile. wish i’d had the plasma table when i built mine it would have simplified things considerably as far as setup and squaring etc, gussets. if you’re moving a lot of sheets or other equipment it could make things much easier. i use my gantry as much as the forks on the loader/hoe because why run the heavy equipment if i don’t have to and now the picker sits folded up in the corner most of the time, but it still has its place for certain tasks.

so anyway, not at all knocking the picker thing if thats what youre using or already set up for or don’t want to spend the extra money or time then run what you brung and just be extra careful with those long arm jacks don’t trust them, they can start sagging at any time. (and i guess if you’re upgrading a picker i’d say some kind of properly rated/certified linear actuator that locks when it stops)

just figured i’d chime in for anyone who reads this later who might be thinking about buying an engine picker but not using it specifically for engines that a gantry sized the largest it can be for your space (preferably big enough to back a pickup under) can be had using a couple large c channels welded into an i beam back to back placed atop a couple upside down T’s made from tubing or triangle like some of the commercial ones, or if you have a source for cheap proper i or h beam stock use that. make sure you use big enough iron, “consult an engineer disclaimer”. i had no trouble lifting a couple 350’s with transmission (one at a time) using 2 5" 3/16th thick c channel welded back to back on top of 4x4 1/8th wall tubing Ts with diagonal braces before i upgraded to larger h beam after twisting the hell out of the beam portion trying to lift it back vertical again picking it with the thumb on my backhoe (whoops should have used a strap for that). before i had the backhoe lifting it vertical took a friend or block and tackle. the chain hoists i have even the cheap HF one seems simple enough not to fail given the repercussions to the companies making them if they did.

also a load leveler and maybe one of those lever actuated magnets for moving sheet steel is probably a good addition to either picker or gantry.

oh something else for anyone considering just upgrading their picker that might be useful for other things: those porta-power units with the long ram seem like a good idea for pulling ball joints etc and the hydraulic rams that come with them are actually designed to work horizontally or upside down whereas most jacks don’t work on their sides. hydraulic ball joint press is something i want to make with this plasma.