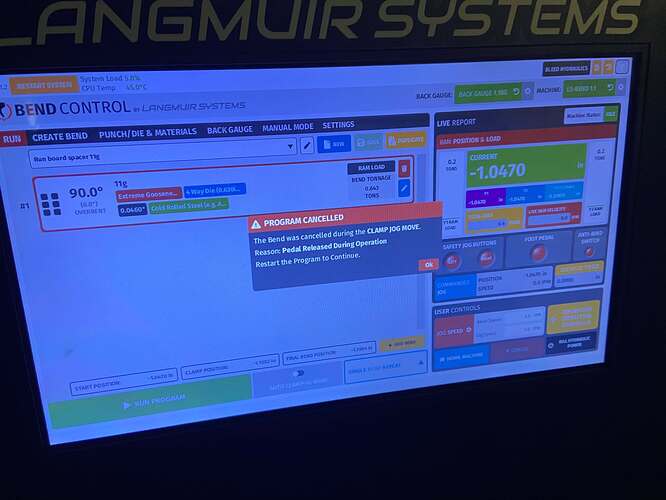

Ok maybe Im missing something. Im on auto clamp off. Iv double tapped pedal, and tried holding it. For the life of me I can’t get this thing to go down with pressure. Keep gettting this error. Im getting to points 1 and 2 and point 3 which is bend, I just can’t perform.

Im at -1.047 clamp position says it should be at -1.102 finalbend should be -1.3664

NM the title of 11g this is just for 18g

The operation is a double tap, but on the second ‘tap’ you hold your foot down. So the operation is:

- Press your foot down.

- Quickly release it.

- Quickly press your foot down again.

- Hold your foot down until the entire bend operation has been completed.

3 Likes

after restart of machine it will apply pressure but only in if the auto clamp to bend icon is clicked to on.

I wanted to run it without any delay, that is why I had that set to off. I have since just added the delay to zero. I tried it multiple ways initially. double tap and double tap hold on second tap and nothing was working. Sometimes I would get the “relase jog pedal to continue” tab.

I hope they will post some videos demonstrating the workflow of this machine. While mine works excellently, I often find myself spending too much time trying to understand their thought process behind designing this software. I don’t want to see metal bending; I want to clearly understand what each button does and why. Just my two cents again.

2 Likes

Yes, like all thier other machines I have bought on faith. Such little demo on things actually being used. When I got my 40t cnc press I figured it out in no time, was bending all my array of parts no problem. This machine takes way way more patience. Im trying to give it the benefit of the doubt. The speed was my number one issue at first, still is but its not meant to be my main source of bending. Its just a learning curve that IMO takes longer to learn, not to mention the many hours of putting it together. Iv still not implemented it into my production yet.

I was bit confused with the backgauge programming. Like you moch it all up in the backgauge tab, then you remember your numbers X and R and then toggle over to “bend” tab and type those numbers in?? Thats what have done so far. Reading the instructions 10 times to still not quite understand is frustrating to me.

Videos def would help. To me the jog arms, and safety features are my least favorite things which Im sure I’ll get used to. The auto clamp delay is useless IMO, this machine is slow enough that once it reaches “clamp” position, it give you enough dwell time as it is. I know it would be slight added costs, but light curtains would be a nice add on and do away with the holding footpedal deal, that for production is annoying. Once I get the hang of it maybe I’ll post up some videos. Im not trying to be negative and Im blown away with some of thier skills over there, but for sure I wish some things can be done differently. I will also say, this was first machine of many I got from them where I was missing parts and the online customer support was very hit or miss.

Give me a call tomorrow at (833) 526-4797 and i would be happy to run you through the process and help you figure everything out. Or shoot me a message at support.langmuirsystems.com with your phone number so I can give you a call today. Our incoming phone lines are off today.

3 Likes

yea that can be frustrating. I was able to figure out the software quick and have been bending lots of parts. but your idea is right.

I set the back gauges manually to get the Y and R, write that down, then use those numbers in your bends. a program consists of multiple bends. In those bends you can add in your comp for over or under bends.

i do agree that there should be a video, might try to get one once i get some parts in.

3 Likes