Lennox blades are great…used them for years in construction for demolition…

I also have the Bauer portaband on the swag off-road table. It’s great, but no good for the big stuff. I like the look of the ez-cut picture, should probably make something like that. The bandsaw is the cleanest and quietest of my saws.

That’s what I use. Wide range of uses. Dewalt makes some decent blades in the 44ish inch size for these as well.

We use this: https://www.dewalt.com/products/power-tools/saws/chop-saws-and-multi-cutter-saws/14-355mm-multicutter-saw/dw872

And it works perfectly. We cut 2" square tube every day. I would use a bandsaw for solid metal, but this is great for the square tubing. We use it for all sizes of square tubing, and it works well for 45 degree cuts too.

One interesting thing we have done with the Langmuir is cut slots in 2" square tube when we were using it under a large table top. Thin slots on one side, then larger ones on the other - so we could put in screws that would have some room to move. The 2" square tube just fit under the torch nozzle.

Still waiting for Box 2 of my Pro to arrive, but one of the mods I’m thinking is taller brackets to cut holes in taller tubes. I think I saw a design on the share part of this site. Lay a 4" tall tube on the bed and be able to cut things into the faces. Holes, designs, text…

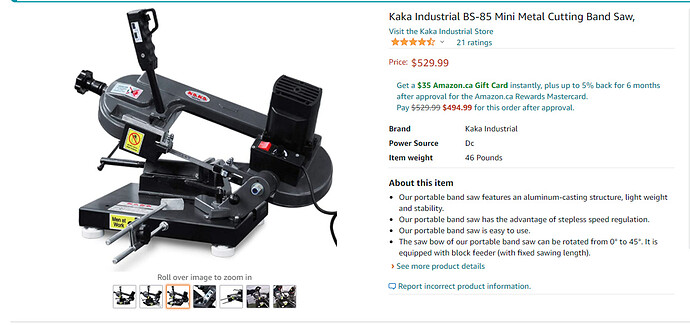

I use one of these, you will never use anything else.

Absolutely!!! I got one of the Evolution saws not too long ago… Been using abrasive chop saws for years but, once you try a dry cut saw, you’ll never go back!!

How long do blades last?

I have a MK Morse 14" Metal Saw with carbide blade and I have cut 100s of pieces of 0.250" wall tube and angle on the original blade and it is still going strong. Let the tool and blade do the work, don’t force it and the blade should last a very long time.

Scroll to bottom:

http://mkmorse.com/circular

Exactly what I was going to say… I have had mine only about a year of so and the blade seems as sharp as it’s ever been… Now this is only with moderate “home gamer” type usage but I suspect it would hold it’s own in a production shop as well… I’d probably always have an extra on hand anyways while the other is off at the “sharpener guy”…

No forcing it though… We have a saying… “Let 'er eat” !!

Love my Evolution Dry cut saw.

Only thing I found was if you cut Aluminum you need to use lube or it plugs up the teeth. Granted I was cutting through 3" of .75 thick stock when it was an issue. Cleaned the blade, lubed it kept cutting.

We have done 4" .25" pipe, 2.5" solid round. Stuff the manual may or may not approve of. just don’t force it, let it do the cutting.

I have used this model for several years and I’m still on the original blade. I have cut 1 1/2" round bar, all kinds of angle, flat bar and square tube up to 1/2" thick. I have since given my abrasive saw to my brother-in-law.

https://www.northerntool.com/shop/tools/product_200641810_200641810

I so bad want to get a new saw…but budget at this time will not allow it…for saw and blade here in Canada I am looing at almost $750…which is around $1.75 usd…hahahahaha…

I was going to get one but the reviews tend to be either “it’s great” or “it sucks and the blade is crap”. Since I haven’t seen one in action I went with the tried & true cut-off wheel. Harbor Freight has a smally 6"(?) metal cut-off saw. It’s like a small chopsaw with an abrasive cut-off wheel. It comes with a fence and a sliding clamp to hold the material to the fence. I’ve cut a bunch of stuff with it - just drop it down to the material and only exert a little pressure, like resting my hand on the saw vs. pulling/pushing it down. The saw does its work. I think the thing was under $80.

I have the dewalt metal chop works great, definitely a game changer in speed and cut quality, and sounds a it less than the model you guys are discussing.

well I bought this the other day…off shore model…

works pretty dam well…except I found the blade size a little hard to find…but for the price…and the cut quality I am happy

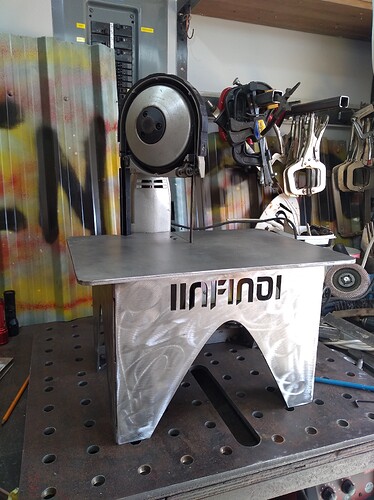

I bought a HF portaband a few years ago when I was down south and one of my first projects with the Crossfire was a stand for it. Basic dimensions were from The House of Chop and I modified it from there. I love it! Added a remote on/off switch and it gets the job done.

I have one (Bauer) with good blades (Lenox) and a similar table to yours provided by SWAG Offroad. The table top has two slots for miter fences which is super handy for straight cutoffs. I also have a foot switch that the saw plugs into that I can then control the saw with. Grabbed that off Amazon or Rockler I believe. That way I don’t have to reach around the back of the saw to switch it on and lock the trigger.

I have the Bauer with lenox blades and SWAG table, also have a Fein Slugger chop saw…love them both