so to sum up the issues and the resolutions…

-

having all that “drying” equipment before the plasma does not mean you have removed the moisture from the air…what does the desiccant medium look like? is it the type that changes color when it get saturated?..have you looked at the desiccant?..take it out dry it or change it.

-

I see a rubber hose…how far away is your compressor and what size of air lines are you using?..3/8" air lines minimum for all hoses and fittings. restricting the air flow means your air will stay warm and warm air carries moisture no matter how much drying you try to do.

-

is your compressor drained regularly?..that is a common problem.

to extend the life of your consumables and the torch make sure your post flow air is set for at least 30seconds…if that adjustment is available on your plasma. post flow air keeps the torch head cool. yours looked almost burnt. -

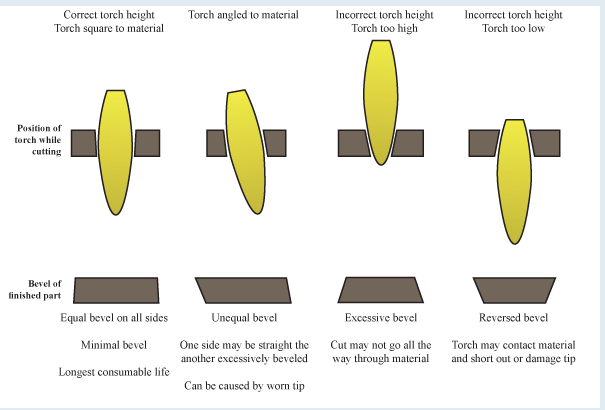

torch head height. have you paused a cut to actually measure your height of the torch head? just because you set the torch height in the software at 0.06 does not mean it will be 0.06. I actually have mine set at 0.45 to get the torch to sit at 0.06. an incorrect height will result in tapers like listed below.

-

next is torch direction…when cutting outside of shapes make sure the torch is going clockwise around the part.

-

when doing inside cuts like circles you should be going counterclockwise.

-

then we look at tip size…make sure you are using the right tip size for the right metal thickness. a small tip size will burn out faster when the higher amps are put through it. George posted a great chart to help determine tip size for amps used on the thread below.

Primeweld Cut 60 Tip Size - #2 by mechanic416

-then you can look at cut speed…once you have a great cut speed giving you nice even cuts…when cutting circles it is best to drop your speed to 60% of what the rest of the metal is being cut at…and of course go counterclockwise. -

start in the middle of circles, there is a setting for that in most cam software. if not do a lead in and an overlap then a lead out.

-

cutting circles of 1/4" and smaller does get tricky and the thicker the material the less chance of cutting good circles…you can mark the center with the software then drill them out for better look.

always remember there is going to be a small bevel on all plasma cuts.

The trick is to tune in the machine with dry clean air…proper speeds…proper amps…then everything else will start to come together.