Where does the cable from the torch plastic guard connect to the control box? I think its the thc connector on the controller box. Im sure its simple. Thanks in advance. Its on the xr, sorry. Msc cable sorry again.

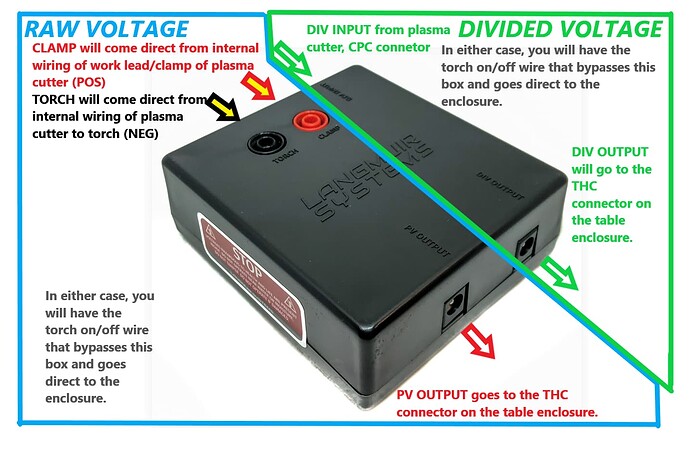

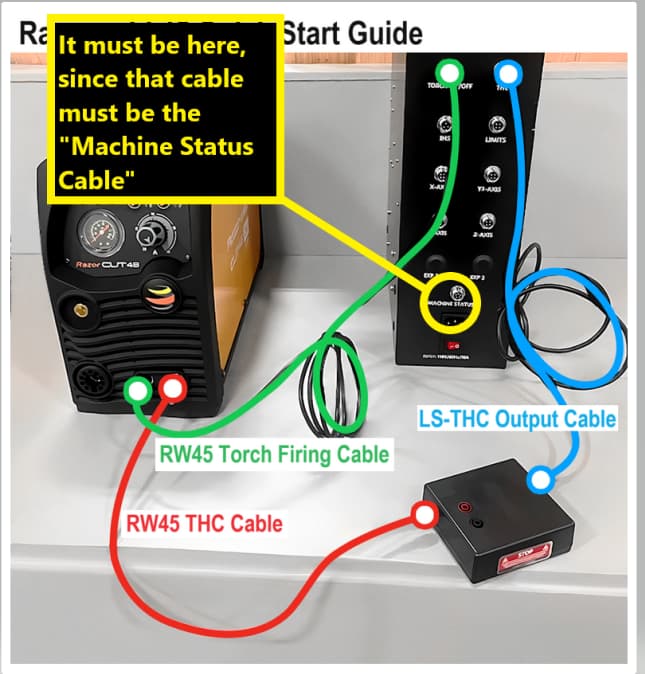

You will have a THC cable but it is a sensing cable coming from the cutter and going first to the VIM Box not the Z-axis. It then attaches to the enclosure marked by a blue line in the second image.

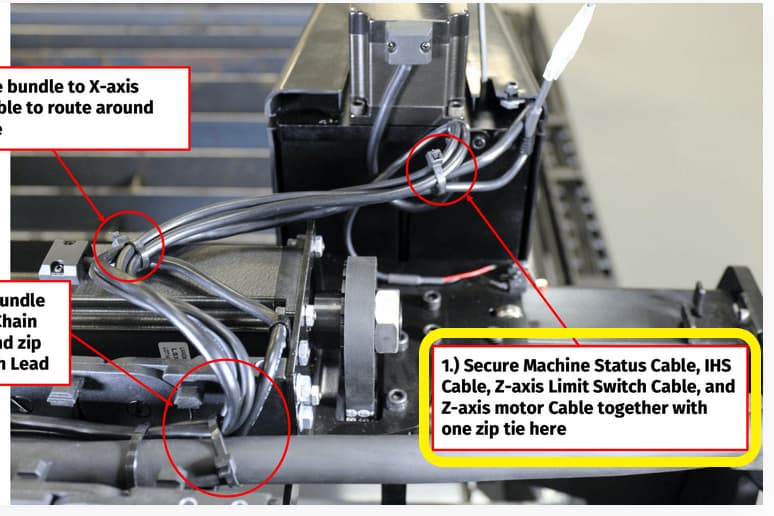

The z-axis bundle of wires has all of these:

I believe the wire in question is the “Machine Status Cable”: It controls the light on the cover over the torch.

The MSC(machine status cable) gets plugged into the “machine status” port on the electronics enclosure.

I am amazed everyday on how fast people can get help on this site. You guys know who you are and its amazing the service you provide. Although I will say Jim’s response times have gotten a little longer! ![]()

I was playing disc golf in my yard. I was just exposed to this game for the first time on Labor Day weekend. I positively love it. I now have three of the baskets in my yard.

It is a nice game to play with friends or practice by yourself. You can play it in most weather conditions such as light rain or wind, which is a bonus for western Washington. Low stress, laugh at each other and a little bit of cheating goes on. What else could you ask for in a game?

bUt diD yOu MaKe tHe bAsKEts?!?

That took a longer time to type that, didn’t it??? ![]()

No. I bought them. Why? Is that against the rules?

Zoom in on the welds if you really want to know. ![]()

![]()

Oh…real funny…Grinder!

wOrTh iT!

Yeah autocorrect kept trying to keep me on track.

No… I just always find it ironic when I, or anyone in this hobby end up purchasing something we could absolutely make.

It’s proof that a well thought out product is worth paying for! Some things we can’t make cheaper or faster or better.

edit I don’t know about you guys but I get asked all the time to copy stuff. I’m like, no their price is good just buy theirs. Lol. I wouldn’t want to make that basket.

These weigh about 30 pounds, easy to take apart to transport in a trunk and are quite stable.

Mine would have been very stable and weigh about 65 pounds and would need to be transported in the back of a pickup.

Lol. The slow increase of price and design time

Can you make this? YES.

Can you make it portable? Eh, yeah.

Can you make it light? Uhhh, probably.

Can you paint it? Ugggg, fine. How many do you want?

One. - Go away.

This type of thing you can make much cheaper as long as it is not inspected. You are paying for the eNgInEeRiNg certification. (Yeah, spell check does not like that)

That’s mean!

It was intended as a compliment. Those things look like they were welded by a robot… Jim’s welds are more “artistic” and have more character. ![]()

![]()

Well played!