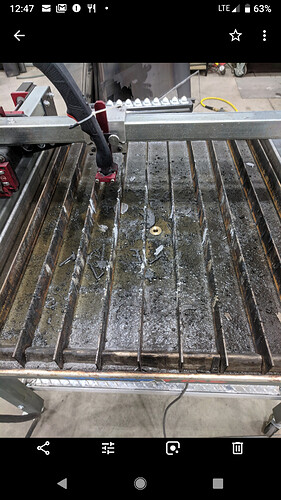

Love my Crossfire but it didn’t take but a few cuts to ugly it up!!?

On a better note “we” have a cut chart started. But learning speed and amps is still not easy.

As long as it kicks out quality work, I don’t necessarily care what the machine itself looks like. Mine definitely looks used. Are you using a water tray?

Yeah I am using a water tray. I set up a quick drain on mine. I empty my tray and shop back the tray between the slats. I can fill it up in 2 minutes using air.

Hi Guys!

Just wanted to clear up any confusion about the slats. They are considered replaceable consumable items and we’ll have them available for a reasonable price in our shop sometime soon (we are working on it now). That said, you should only really be replacing them if they start to have dips that affect cut quality- not looking less than pretty. We have cut a ton on slats and they will last you a very long time.

With a little extra work, chipping some slag off, you should also be able to flip them over and use the fresh edge for double the cut life.

The rest of the machine cleans up pretty well if you are so inclined but plasma cutting IS still a fairly messy process.

Got to move the material in different places to keep the table even also. Didn’t think about turning them over though!!

I’ve got one we’re adding to here for the Razorweld 45. If you’ve got the same torch and willing to share your results I can add them to the our sheet to help fill it out.

I do have a 45 and if I have successful cuts I surly will tell you. I need 1/4” feed and amps. I imagine 45 amps but the good feed rate would be welcome and shim.

Here’s the Google sheet we’ve got going so far.

I flip and rotate my slats out

Says my access has been denied?