Hi, I was wondering what is everyone using for a break that isn’t a small fortune? Im mainly working with 16 gauge, but I do cut stuff with 1/8 (11 gauge) and 3/16 ( 7 gauge), but everything I look at, the max that it well bend is 16 gauge, I live in Newfoundland, Canada so I dont have access to harbour freight. I think princess auto is similar. just wondering if anyone bought anything that they fine good or if they made a brake themselves and finds it does the job just to give me an idea,

Well, here is an idea if you already have a shop press. Size of metal is definitely a limitation, but at least it is a starting place for ideas. Dang, the design is so simple you might be able to create one the width of the shop press. Certainly has my design juices going.

yes, ive seen this and I dont have a a shop press but I think this is the cheaper route to take to get something that can bend thicker metal without breaking the bank, I was just wondering what people were using before I went out and bought something, My plan is to have a sandblaster cabinet and an area for powder coating, and an oven to bake it in and a brake and maybe a roller. I have a powder coating gun and an oven, its not hooked up yet because Im new into this. Just trying to get ideas on what I can get to make me put out better quality material.

i just bought the harbor freight 36" brake. gonna do a few mods to beef it up. figure its a start.

yeah I was looking at that one as well in princess auto version because im in Canada, but the max it does is 12 gauge, and I was looking at something that can bend thicker.

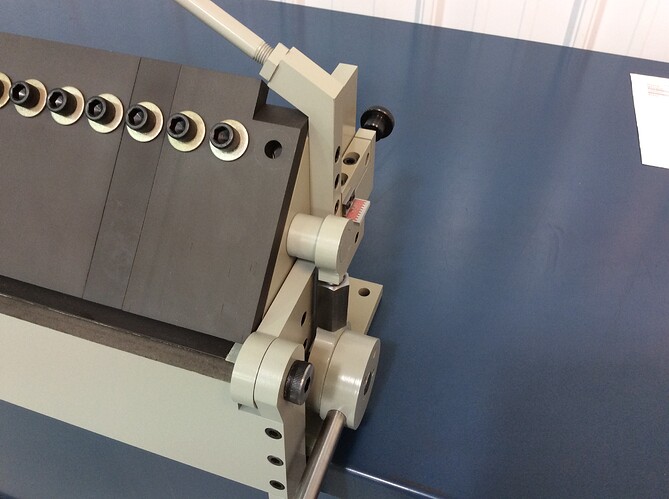

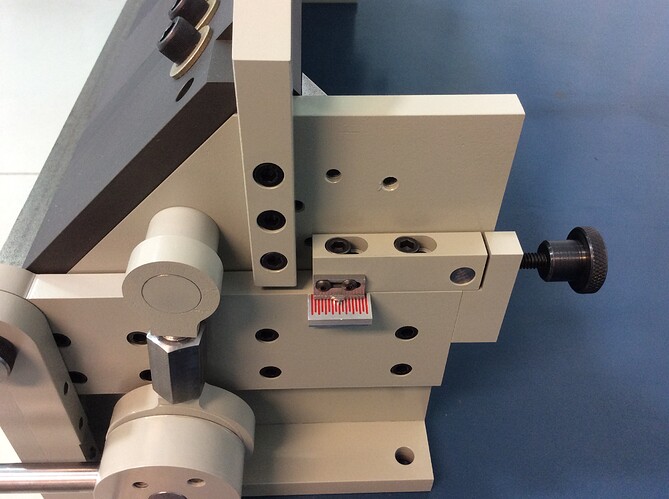

I built this one and just bent some 16 gauge on it yesterday however that was pushing it to the very limit. Been thinking about building a bigger and more capable one some day. I could email you the cad drawings if your interested. You would need to make some mods though to bend the stuff your talking about.

That’s amazing, very well done and put together. How thick is the metal used for making that? I use inkscape and sheetcam, I find it easier to use, but you can email the cad drawing if it isnt too much trouble. my email is shanebruce@hotmail.com.

Would love to get the cad drawings for this. Looks great! Zimmermanmotorsports@gmail.com

Almost everything is 1/2 1018 cold rolled

Sorry for being slow with sending out the drawings. I get them sent out shortly.

I bought a “williams lowbuck lpb plate brake” back in early 2000 for less than $100. I think company went out of business but it could easily be duplicated with minimal skills. It will bend up to 5/16" easy and 1/4" with some effort.

You got a deal then, Im looking for something to bend around 2 feet of material so im just seeing what everyone else is using or would suggest that wont break the bank

I emailed the drawings this morning. If I missed anyone let me know here and I will send them out.

Thank you so much, It shows you have put a lot of effort into making it, you have a good setup with the Machinist lathe.

Please email it to me to: formula350lt1@hotmail.com.

Very nice work mate!