Hello everyone

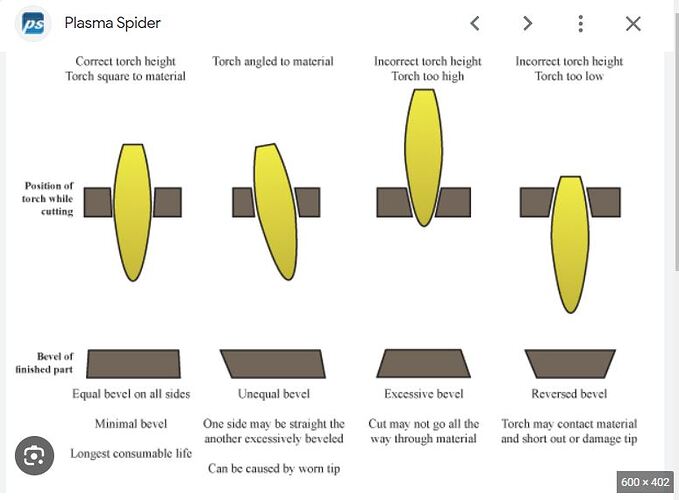

I’m cutting 3/8ths material running some test cuts and they’re coming out clean until it hits the corners they bevel in and come out rounded towards the bottom of the cut

Cut height: .04 (used feeler gauges and .04 gives me the .06 I want)

Ipm:20

Amps:45

Psi:90

Pierce time:1.5 sec

Kerf width: .07

Pierce height: .04

That’s the nature of plasma cutting. The plasma stream trails behind the torch and the torch turns the corner before the bottom of the steam can catch up.

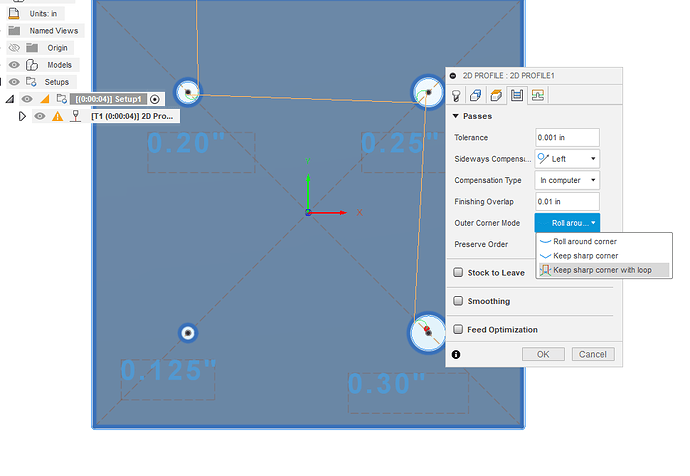

Whatever program you’re using, figure out how to slow down for corners. In Sheetcam it’s a simple path rule. In Fusion, it’s feed rate optimization.

You could also do a dog bone in sharp corners, where it goes past the corner and circles around before cutting the next side. This is as easy as checking a box in Sheetcam. You would have to design that feature into your part in Fusion.

Thank you for the response I’m on fusion so I’ll try to figure out how to slow the corners down thanks again

Feed rate optimization tab in the cut profile menu. It will solve your issue about 80%.

Plasma cutting 1/2 and above is not an exact science.

I had seen you post this in other discussions which helped a lot with the beveling the long cuts come out fine I think if I just slow down the corners how others said should fix my problem

Does fusion not have a “loop sharp corners” equivalent to sheetcam?

That function does not apply to 2D plasma-type profiles. At least as far as I know. I have never tried it.

As we all know, the shape of the plasma arc is an elongated football shape. When you start cutting 1/2 and above, there is no way around a slight edge bevel.

It does. Keep sharp corners, round corners, and that third option that i can not remember the name.

I googled it out of curiosity, but i couldn’t tell if that was automatically adding a radius or something.

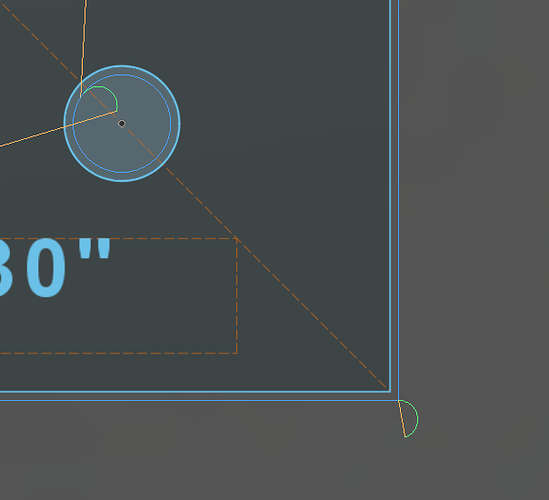

You probably already know this, but the loop sharp corners in sheetcam moves the torch beyond the corner, loops around to start the other direction straight on so the torch never makes a 90 degree change on a cut path.

Same with the “overcut internal corners” setting

As Sticks said:

In this example, you can see it will go past the end of the plate and create a new lead-in at the corner.

(I have never done it.)

Ok yeah that’s the same thing. I don’t know why but the names used for it don’t conjure the right image for me.

The only application I see for this is the thick material where you want that corner as square as possible.

It won’t work as they want it to. But you are completely correct. @brownfox