That is interesting. Like I said I have seen that suggestion many times. My thoughts was always it would certainly show a severe moisture problem. Not one where anyone had much of a attempt to remove moisture. My train of thought was as soon as dry air came in contact with " undry air" it would be a sponge and start soaking.

Can you show a picture of how you were using the 123 block?

I do often get swirl marks on my electrodes.

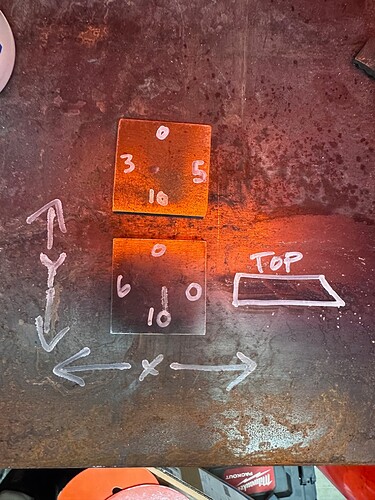

Ok. So believe it or not when I run this program and measure under the Nozzel i get .120". I have to edit the G-code to a cut height of ZERO to get a distance of .062. I have never actually measured this before. This may have been like this for the last 3 years. Though I don’t think this is my only issue.

I am afraid of that. That could be a very real possibility. Someone posted a suggestion to try my hand torch. Once I figure out the cut height I think that should be my next step.

next make sure your not getting a premature ihs trip. manually drop the z and watch for the ihs light in fire control. it is possible the torch is mounted to high.

post a picture of your electrode.

Good catch. The z was getting hung up. Now with a a G-Code of .06 i measure .079. I threw my hand torch in to see if i could get a better cut.

This was using the hand torch with the consumables featured in the photos in the first post. Already improved from the machine torch.

That nozzle won’t cut straight it can’t. When I cut 3/16 or thicker I make sure the plate is square to the torch in x and y. The way I did my table on setup is I used a level instead of a square on the torch mount. Then when cutting something I am looking for the best edge quality I level the plate as well.

@Vernon here is a picture of a electrode I understand to be moisture. Still not saying moisture is a issue for you.

How long does your beads last before you have to change them? Is the larger canister the bead dryer?

Yes the stainless is the dryer. Now I must admit that’s essentially homemade. That was a very nice water filter that I put a down tube in. I would say that when I change the beads they never really change pink. I would say about 5% turn a light pink color. The rest are pale blue.

I do have a 20 year old harbor freight drier. But I’m not sure its working properly as I never get any moisture out of it. Gets cold though.

[quote=“Phillipw, post:31, topic:35131”]

electrode I understand to be moisture

Yes my electrodes often look like that after a while.

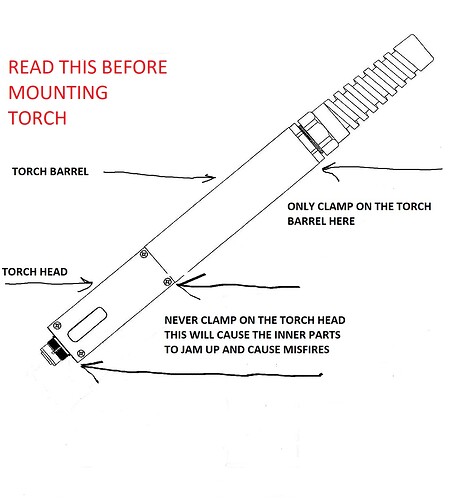

I will get on fixing that. Do you think having to re-tap the electrode hole could be causing a large part of the issue? Are you able to replace those internals with out needing an entire new setup? I guess there could have been damage from clamping in the wrong place.

Really think your issue is the cut height mostly. Looks and sounds like you should have a hold on your moisture.

Then as @mechanic416 said you need to drop your machine torch down. Clamping there can interfere with the movement of the electrode.

I would re cam your test square with a .040 cut height and see what you get.

Pop the hf dryer open and make sure the trap inside isn’t full of water. You do have it before your bead dryer right?

If you broke a electrode off or messed up the threads you will need to replace the torch head. You can not repair the torch head. So if the electrode is not screwed in complete straight it will cause cutting problems.

![]() Can you add one to my order. I’m invoice 1079. I haven’t paid for my consumables yet.

Can you add one to my order. I’m invoice 1079. I haven’t paid for my consumables yet.

Let me go in and see if I can add the torch head. If not then I will send you a new invoice and cancel that one.

Updated invoice has been sent.