I did a upgrade on my table I can move 48.250 ish by 36.5 ish… well over 48x36.

Link to details?

Oh I can’t take credit. I was meddling the idea decided to check on fire share to see i could remember some making a post earlier about a upgrade.

Anyhow I cut the plates I had downloaded off fire share. Works great. It removes two bolts from the plates. They also raise the x axis up a couple inches. With it raising up I would recommend a machine torch because with a hand torch it drop the torch holder very low.

This might be what you are looking for:

https://www.langmuirsystems.com/fireshare/crossfire-pro-gantry-riser

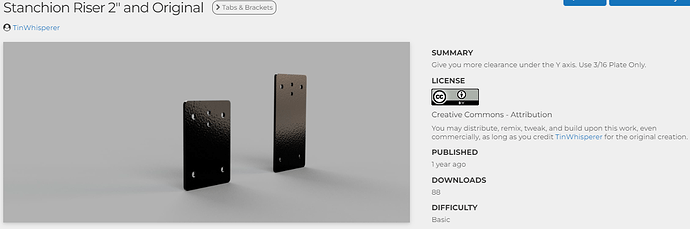

or this one:

https://www.langmuirsystems.com/fireshare/stanchion-riser-2-and-original

I am marrying the two designs to get more Z height for cutting box tubing, and a legitimate 36" Y work area.

I’ve been planning on doing the stanchion risers for a while now and mine will be quite modified too. I think I can get away with a 1/4 inch stanchion riser on the inside and a 3/16 on the outside. I think it’ll help because I plan on doing quite a high raise. I want the majority of my long torch to be below the center of the z-axis.

I just recently upgraded to a machine torch. After my table upgrade the torch holder was so low on the z axis that I was afraid it would move to easy.

The upgrade added a couple inches in height. My machine torch seems to balance nicely. Doesn’t seem top heavy.

Remember on the size that you need room for your kerf. If your table cut are is 33" you have to subtract double the kerf off each side or you’ll hit your limits. With limit switches I can cut a straight Y cut 32.5" but would only be able to get a part 32.375" in the Y plane. Not a big deal except when programing part especially if doing an index cut.

@TinWhisperer - Why the 3/16" limit on the outside?

Because either end will move out relative to the bracket that holds the backlash nut. Pushing the lead screw out of alignment by 16th of an inch where it’s in contact with the black lash nut.

If you altered where the backlash nut was mounted then you could

Took me a minute. The bearing bock.

Have to either stay with oem dimensions, or machine to thickness at the bearing block mounting.