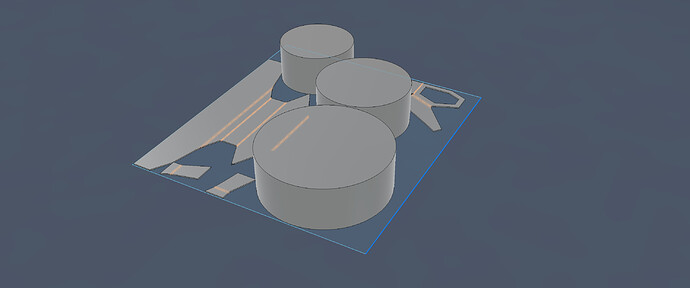

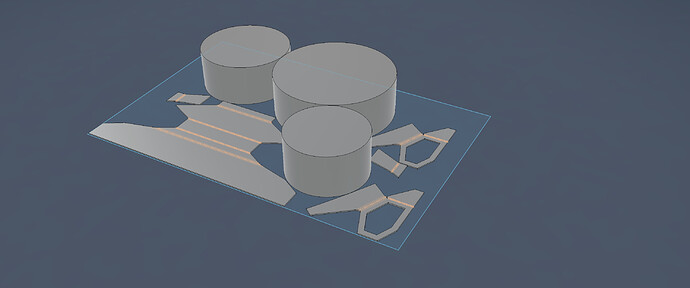

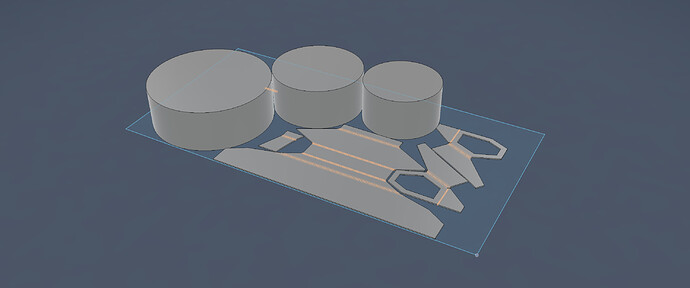

Arrange is used with components.

Both

Flat Patterns and Bodies can become components.

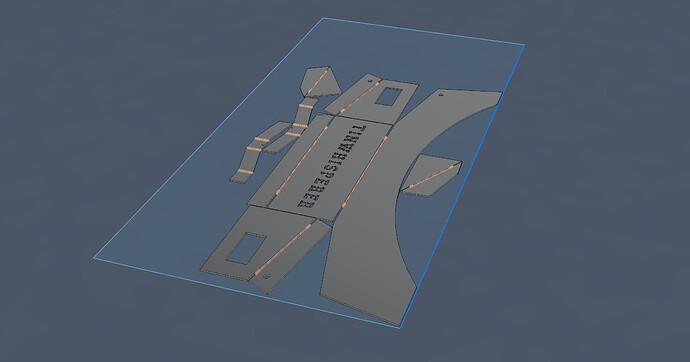

Here is an example of several flat patterns and a few random bodies all nested using arrange.

All the bend line information also stays intact when the flat patterns are moved to different arrange locations.

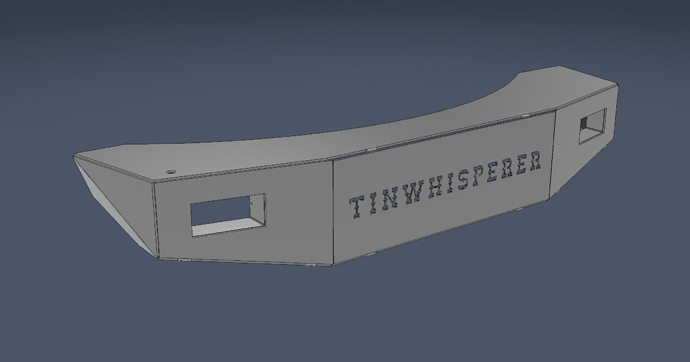

here is the example bumper i made for the live stream of the sheet metal tools. It is not really complex but the 7 sheet flat patterns Arrange nicely.