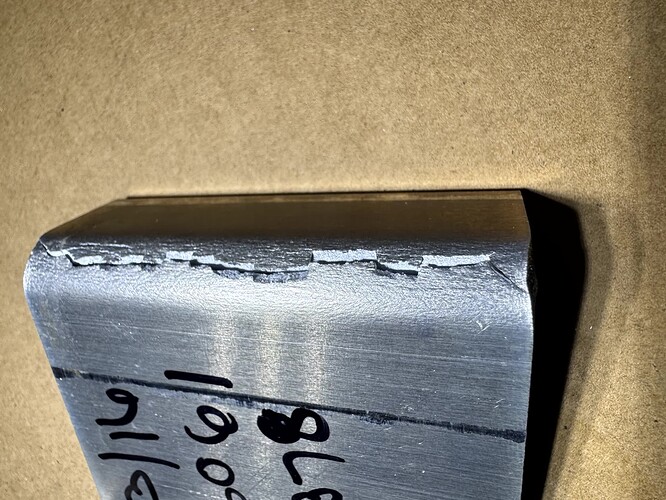

So first - I never bent aluminum. So at you can see from the pics - this is what i am getting. Cracking on the material. I asumed the die - so tried the 2” die and still see cracks yet very small. you can see the makings i made in the parts to what it is and what i was using. Now from what I was reading on bending aluminum - different grades will bend different. Is this just happing becasue its 6061 or is there something I am missing here

6061 is a temper aluminum it can’t be bent without any issues. 5000 or 3000 series are best

thats what i thought

If you are machining aluminum, 6061 or 7000 series are best. 7000 series are not weldable without problems or bendable. It is mostly aerospace shit.

It appears from the photos of your sample bends that your bends are parallel to the grain of the material. With hard materials such as 6061-T6/T4 or 4130 Chromoly steel, bends should always be made as perpendicular to the grain as possible. The bending of 6061 is possible but an extremely generous inside bend radius is necessary and the necessary bend radius increases somewhat exponentially with the increasing thickness of the material. Your sample bends appear to have way too small a bend radius. Another factor to consider when bending difficult materials and hard materials is the preparation of the edges of the material. Your bend samples appear extremely rough on their edges. When bending difficult materials, it very important to prepare the edges of the material prior to bending. The edges should filed/sanded as smooth as possible and then polished out (I use non-woven abrasive wheels on buffer), If you do not polish out the edges of the material prior to bending, cracks will propagate in the corners at the edges. If the part you are making has multiple bends at 90 degrees to each other arrange the cutting of the material so the bends will be at 45 degrees to the grain of the material. There are charts you can find on the internet that specify minimum bend radii for aluminum alloys.

Depending on which temper level (T5 T6 etc) you might be able to heat up the bend area with a torch and pull out the temper. If you have to use 6061 for some reason like it’s a one off that is going to be welded you might be able to play with it and get it to bend once. You should be able to get 6061 to do 45 degrees if you can redesign the part to have 2 bend a little bit apart, or adjust the radius diameter (larger). But as others have posted best bet is pick a different alloy unless it has to be 6061.

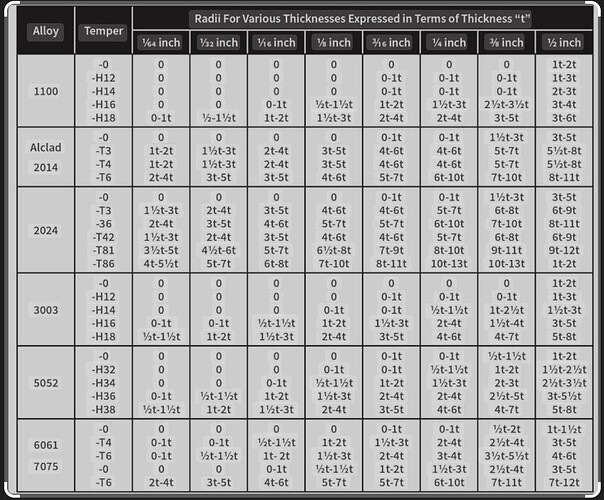

We build full size aircraft using 4130 steel and 6061-T6 aluminum. The main issue is not having the correct inside radius related to the material thickness. If you are using the dies from the T-25 the radii on these dies are way to sharp/small for this application, a common problem. You will need to increase the radii of the die per thickness of material … see attached chart.

One trick we use is to put a sacrificial piece of sheet material on top of the material you are bending. You need to figure the thick of this material to match the correct bend radius of your part after bending. Just do a few test samples and record the thickness of the sacrificial piece of sheet material for future reference. The other issue is … bend it very slowly to let the outside of the bend material to stretch.

Hope this helps you. …. KAP