as stated at the top of the thread…it is a standard skateboard bearing…available at most stores for bearing replacement…skateboard stores…or reachout to the support email from Langmuir…and they can ship them to you also

No bearing stores near me…and I have reached out to Langmuir systems as stated in my post and I can’t reach anyone…

you said you called them…have you tried emailing…this often gets faster results…it has in my issues…and I have had a few…

mis-formed water table…answered in 1-2 days and new one shipped

blown main board…multiple emails and fast over a coule of days…new one sent within a week

trouble shooting…same day usual response…

do not take this as a lot of problems with a table…I was one of the very early people who got a table…and the bugs were still being worked out.

I love my table…

Amazon has the bearings also…

great thread for information

I’ll shoot them an email and see where that gets me. I have had the table since January of this year and haven’t really used much until lately and that’s when I started noticing some issues with the carriage which led me to dive deeper where I found the bearing issues…I think it’s a good table all in all. Sure beats cutting anything by hand.

If they are standard skateboard bearings then these should work.

FYI a higher ABEC number on a bearing is a tighter tolerance, I used to work at a roller rink and an abec 9is a significant upgrade over a 6 like what’s posted above me!

Lubricating your bearings regularly enhances their longevity.

Lubricants primarily function to clean, protect, and lubricate your bearings. When applied regularly and sufficiently, a lubricant eliminates friction, making your bearings perform faster without obstruction. It also can repel moisture to prevent rust and corrosion and builds a barrier against dirt, grime, and other contaminants that hamper the performance of your bearings.

im having the same issue ive tried every possible combination pre load removing cleaning etc etc . The motors appear to fire at opposite times it will run at say 100ipm anything higher binds it up. break in tap also doesnt work it just slips off the get go.

if the motors appear to fire different then I would double check your couplings to start.

then try to change the plugs on the Y axis back and forth…see if there actually is a problem with them not starting the same…

then I would look at your gantries…remove the drive scews and check how smooth the rolling is and if your table is truly square.

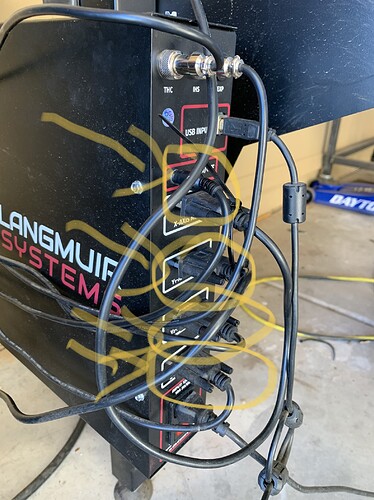

So after a tedious job of replacing all the bearings in my press it glides across now. So I was noticing some weird noises from the motors and binding in spots where the gantry would stop where it would glide across before installing the drive screws. I walked to control box on the table and checked the serial cables they are all tight but where it would bind up on the gantry I toggles the cables and sure enough they would power past the binding spots . The break in file also had problems unless I toggles the cables I can assure you the serial cables are all snug and tight there has to be a bad board connection inside the box to affect the x axis and Y axis. . Hope Langmuir sees this and sends me out a new control box .

contact them through the support email from the main website…that way they can send you a ticket number for solving your issue

I expect you meant “touch the cables” not toggle. But I believe there were some control boxes where the USB connector shells weren’t properly isolated from the box and they were grounding out. That might be the issue here.

I just got an email with a bill from Langmuir for the replacement of a control box that has less than 10 hours of cut time on it !!! Are you fricking kidding me??? Spend all that money and never really have a reliable Cnc table and still have to make modifications and get charged for something you didn’t break? The zip ties are just holding the serial cables up with less than fingertip pressure to ensure the motors don’t misfire and ruin a cut. Wow all I can say as soon as I get this table up and running I’m selling it and getting something better. Sorry it’s been like this since I got it. One thing after another with emails after emails on what the problem “could “ be only to figure it out on my own and be charged for parts that were either incorrectly built or bad craftsmanship period.

I agree, the quality of the fit of the serial cables is pretty variable on my machine, and none seem very solid.

Fortunately it hasn’t caused any issues with my machine. I have been lucky to have a flawless experience getting up and running besides a power supply that they got me quite quickly under warranty.

The cleaner and greasier your bearing, the better it will rotate. When using solvents, the polymers in the bearing might be completely removed, reducing the lifetime of your bearings. Remember that olive oil should not be used as a cooking oil on bearings. However, it is preferable to nothing, and far better than using a solvent.