Are the ball screw assemblies backlash/preload adjustable on the XR or are the units sealed? if they are sealed do you have a price for replacements if backlash ever becomes out of tolerance? also your assembly instructions say to lube with either oil or grease. is there one that you recommend more than the other? @langmuir-daniel @langmuirsystems

On the Crossfire I use grease or oil, whichever is nearest my hand at the time when I’m near the machine (I try to do shop maintenance every Saturday). IMHO both work equally well, no issues. When the leadscrews get dirty WD-40 a brush and a rag does the cleanup.

from what i can see the crossfire has basically a NUT of sorts that stays stationary and the shaft spins. the XR looks for have an actual ball screw assembly that spins on the shaft. that assembly if like other machines i have ran contains small little ball bearings that rides on the stationary treaded rod. thats why i was curious if there was a certain lube they prefered. ive ran machines you just drop oil in and i have ran machines that actually have grease fittings on them for a grease gun.

The ball nuts themselves do not have a backlash adjustment and backlash lands somewhere between zero and .001”. The ball nuts have plastic scrapers that are backed up by felt wipers on either end. We don’t expect to see much wear from these parts since the screw, nut, and bearing balls are all heat treated to 55+ HRC. The need for replacement would be based on whether the backlash causes measurable defects in the cuts.

Grease or oil works fine, I tend to like grease because it requires less frequent lubrication. Usually use general purpose wheel bearing grease.

You can either shoot grease/oil through the lubrication ports or apply directly to the screw. The felt wipers absorb the oil and allow the screw to stay lubricated. Their primary purpose is to wipe away the abrasive dust.

And dont ever hold up the screw by you hand and let the ball nut run free, it will run off the screw and hit the ground and you will never get the tiny little balls back in. Dont ask me how I know.

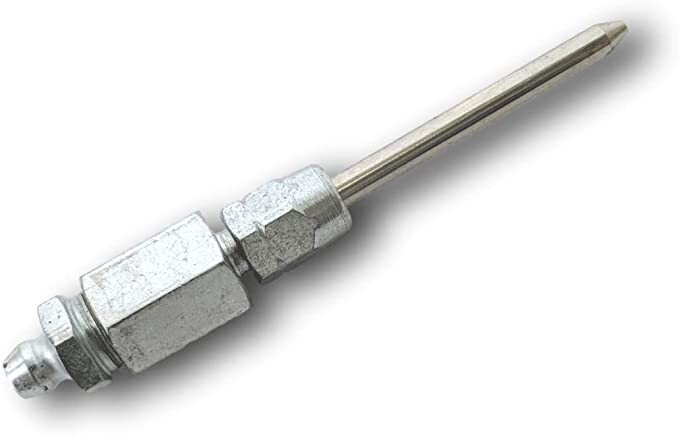

The threaded hole in the ball nut that you put a plug in, could a grease zerk be put in the threaded hole and grease it periodically?

yes but we dont recommend keeping a zerk installed there because its a snagging hazard.

Then use the needle grease to install grease.