I cut of bit of quarter and 8th-in aluminum.

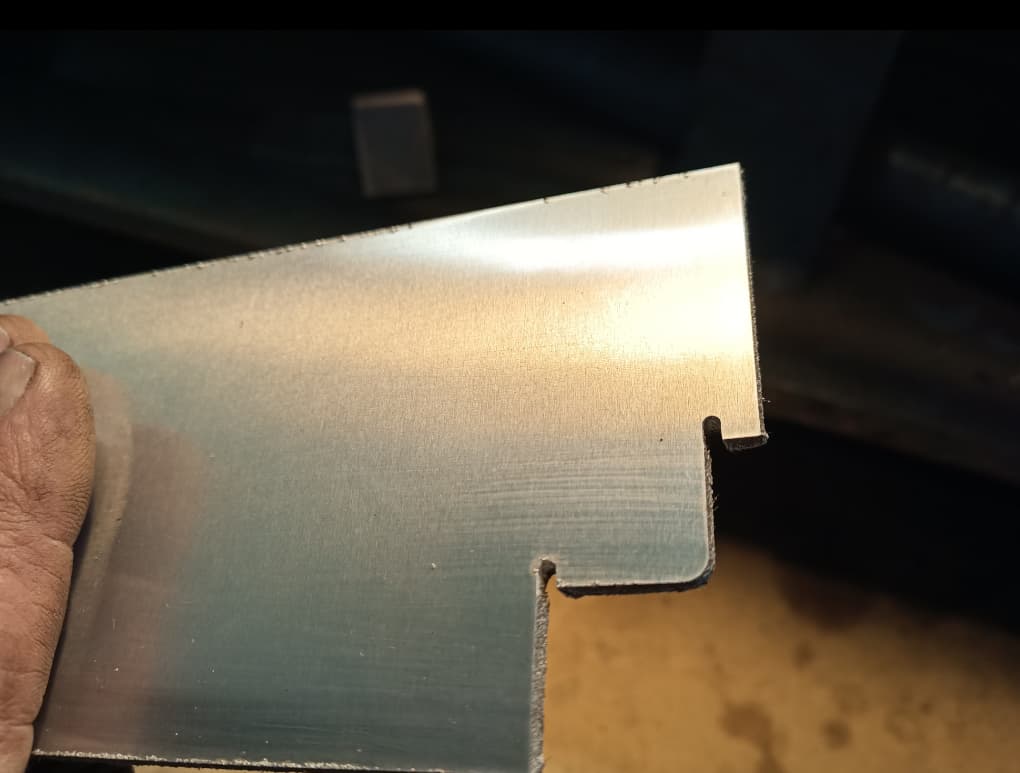

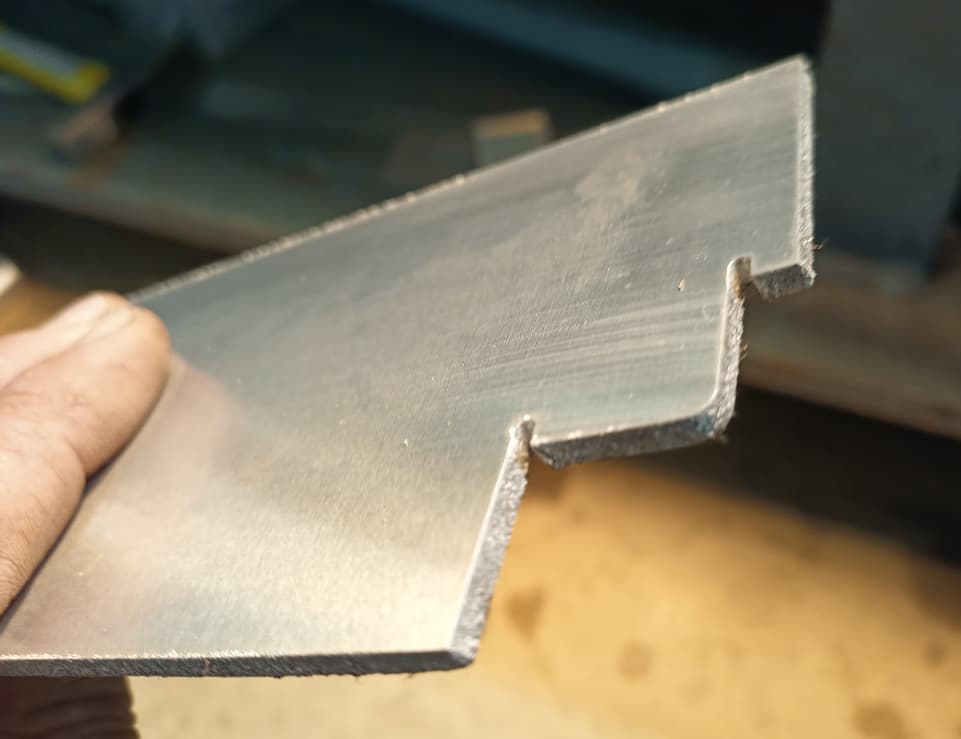

Here’s a recent project of quarter inch aluminum. I used 65 amp shielded book settings from the hypertherm manual.

I end up getting very little dross. The most stress I get on the cut is when you’re cutting a line parallel with one of the slats and very close to it.

I actually ran an eighth program the other day where every piece came off and I don’t think there is any cleanup before going through the rollers.

For my aluminum cuts I normally use the 65 amp consumables.

[IMG_20240917_081723]

[IMG_20240917_081722]

[IMG_20240917_081720]

[IMG_20240917_081718]

[IMG_20240917_081716]

[IMG_20240915_132805_737]

[IMG_20240915_132801_012]

Made a few more of these in a different sizes

Quarter inch aluminum for the main body. 3/16 aluminum for the large rings and 1/8 inch aluminum for the small rings.

Cut all the aluminum at 65 amps. Straight book settings from hypertherm. It all cut very clean

Clean enough to assemble it straight off the table. But I did dress …

These cuts that aren’t even pulled from the table yet basically zero to dross.

@asummers509 The bumper you posted the link for would not require the use of the sheet metal part of fusion 360 .

Sheet metal components are used to bend compensate for bend allowances. The picture of that jeep bumper has no bend components, it is several flat pieces tacked together.

@Simsworx is right, using proper file structure is critical when dealing with more then one sheet metal component .

So considering there is no bent parts in the example I could put together a video on how in …

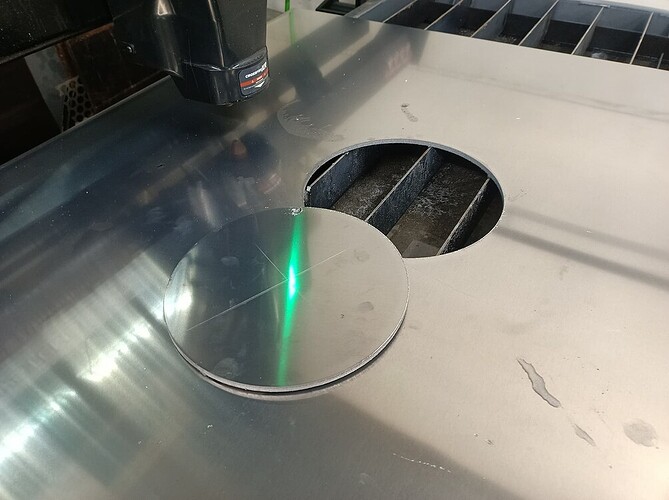

I cut some floor panels for a dive barge today.

Some of the panels were almost the entire cutting area of the langmuir pro.

[PicsArt_12-04-06.28.21]

And the z-axis compensated fairly well with the diamond plate uneven surface height

1/4 inch aluminum diamond plate.

[PicsArt_12-04-06.24.13]

I was running a Hypertherm PowerMax 85 set at 65 amps.

Here are the parameters I used.

[PicsArt_12-04-06.39.56]

I was pretty apprehensive because this material is expensive but I ran the most compl…

Even have decent cuts on diamond plate.

I’ve had decent results with aluminum. I stick with Hypertherm book settings with a 50% turned down for optimization.

Aluminum is the most fickle to cut consistently.

6 Likes