How about another spin on the great air quality debate.

We had a discussion in a thread about desiccant dryers that has me thinking. I always look for ways to improve and use what I have at it maximum efficiency. In that thread it was mentioned that desiccant beads need temps below a certain point to work. That made me think what off they had a specific high and low range. I have a desiccant filter immediately after my refrigerated dryer. We discussed if my air was to cold for the beads to work efficiently.

Out of curiosity I added a desiccant filter down stream to see how long it would take to see any change in the beads. I have used enough air I think I should see a change by now. I opened the filter up to find pretty blue beads and rusty dust due to it coming straight out of a dry air tank before being filtered.

I don’t claim my setup is right. It seems to work well and I am satisfied with the performance of my plasma consumables. I am just curious as to where I am at.

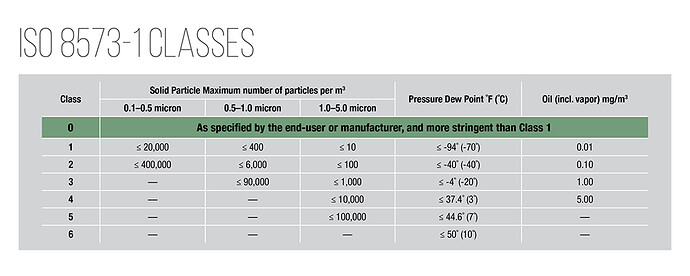

So I sent a email to the company that make the beads I am currently using and asked there thoughts about this situation. I even asked them about meeting the standard of air quality ISO 8573-1 Class 1.2.2. air at approximately 6-9cfm. Just to see. Thank @TinWhisperer for this information.This was the response I received.

Now I am wondering about a inexpensive way to test my air and get a idea even if not completely accurate to get a baseline. I have a regulator I use on my powder coating hopper to lift the powder or fluidize it I can regulate it down to very little pressure. I was thinking if a person could get a hygrometer that will read low enough. I might be able to make a sealed container put the meter in it and purge the container with my air supply to get a idea.

The first issue I am seeing the lowest reading hygrometer I can find only goes down to 1 percent RH. I know this won’t be fool proof but I could be a base line.

Hopefully it may help someone in the future and if not it will give @chelanjim a watch this guys experiment.

What are your thoughts?

1 Like

hmmm…I am going to talk to a friend of mine who is a service tech for a major medical gas service company…

he services all types of gas systems and one in particular Medical Air systems…looking to him to find out what are the technical requirements for medical air RH…and see if he can possibly test mine for giggles…

3 Likes

I’d be very interested in what he has to say.

I would guess it would be this.

standard of air quality ISO 8573-1 Class 0.2.0.

They are likely using oil less compressors in medical systems as well.

I’ve also been searching for something inexpensive like this. A digital hygrometer to measure pressure dew point would be the trick but they’re not cheap. I’ve been looking on eBay for used ones.

The other little factoid I should add here is that when using the new hypertherm SYNC they’re way less susceptible to moisture.

standard of air quality ISO 8573-1 Class 1.4.2.

So basically you wouldn’t need desiccant at all if you have a good refrigerated air dryer.

1 Like

That is great. I am sure you would use one on your daily job more often than I. I don’t really want to spend a lot to use it a couple times.

I actually put the one I have in a sealed food container last night. Pulled straight out of my coalescing filter which is right after the desiccant.

Shop humidity was 38 percent. It quickly went to 16 percent which is as low as the meter would go. I had a 10 ft air hose going to my regulator from there was a 1/8 airline. The air warmed up to the point of room temperature before it made it to the meter. There wasn’t enough volume moving. I let it run well over a hour wanted to get a better idea of the air temperature. I don’t really trust a IR temp on the pipes to be actual air temps.

1 Like

The collessing filter should really be before the desiccant. Downstream.

Hopefully there’s not enough grains of moisture in the air after the desiccant to colless into a drop

1 Like

I have one there just to catch any desiccant beads that make it out of the filter itself. It does happen not often.

1 Like

Like I said before I know my setup isn’t perfect I always look for ways to improve. It is dry enough that I have been getting a brown powder dust in my filters that comes out of my dry tanks. That is why I also run at least two screw on filter in addition to the rest before my powder coating setup. Talk about ruining a nice paint job.

2 Likes