There is not any water going to make it to that plasma cutter no way ![]()

Adsorbs

Sorry I can’t help myself.

It may seem like a lot of stages but each stage plays its role within a particular range of dew point extraction.

Yes that is a great set up but most people are never going to go to that extent for just a plasma cutter.

Read that article that I posted from plasma spider and tell me what you think of the last post by Jim colt.

Ok I see the difference, but when people read that they wont. They see something that removes water.

It seems to describe exactly the system I have.

Minus the dry air storage tank

And they’ll suffer the consequences with reduced consumable life ,reduce cut quality, reduced equipment life and potentially more failed cuts. Which will all be a mystery to them so they can point fingers at every other thing but they’re in proper moisture management.

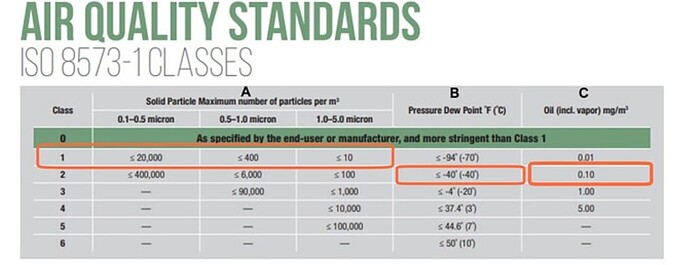

He does mention the 1.2.2 air standard which is -40° C or Fahrenheit dew point.

I see the last post on that plasma spider topic I’m going to read that a little bit more thoroughly.

Was this directed at the Campbell Hausfeld kit I posted? It has a desiccant media in it, that changes color when it needs replacing. What am I missing?

I have to say it speaks volumes for the Langmuir product that you guys have this kind of time, effort, and money into your air systems, and elected for the lowest priced imported CNC Plasma setup on the market. I know that might read like a back-handed compliment, but that’s not how I intend it.

But as someone who is attempting to run a Primeweld cutter on a Langmuir table, it should be obvious that I am wrestling with a very tight budget. My air compressor is a 30 year old 60 gallon Devilbiss unit, with a grossly overrated motor, and it’s still hanging on. That’s going to be the weak link in my system. All in, I’m at just under $4,000, without any kind of air management.

I apologize I did not see that had desiccant. They make some that look just like that but dont use desiccant and don’t work very well.

As far your set up, read the post I found on plasma spider. You can see this topic goes from one end of the spectrum to the other. Before you spend a bunch of money read up on the subject as much as you can. That way you will know where your weakest link is and that will help the most.

For most of us we are using compressed air for many other things.

If you are just running a plasma cutter buying all that will be a tough pill to swallow.

Sorry about the slow response, super busy day at work. Yes, the cooler is to reduce the chance of condensation.

I am also using a PW CUT 60, and like you I am using an old compressor… one my dad had in his barn that I resurrected with a HF 5hp pump. I am guessing our budget is pretty similar. I started with just a water separator off the tank(existing), and a 20-gallon tank scavenged off another dead compressor (also in the barn) to use as a “dry” storage tank and desiccant and a particulate filter. I have been collecting the components for the after cooler over the past months as my accountant (read wife) has allowed. I now have everything I need but the time to put it together.

I had to cash out early on my inheritance (the two dead compressors from the barn) ![]() to get to where I am now.

to get to where I am now.

I would start with what you can afford and upgrade as soon as you can. It will benefit you in the long run to improve your air system as outlined by others above.

That is crazy!! I am sure you already have it all figured out.

It’s a “temperate rainforest” ![]() But it comes in gallumphs vs spread out in small rainfalls. That means even though it’s twice as much rain as we get in CT, it doesn’t rain any more days. It does mean needing to build & prepare for inches of rain in a single rainfall.

But it comes in gallumphs vs spread out in small rainfalls. That means even though it’s twice as much rain as we get in CT, it doesn’t rain any more days. It does mean needing to build & prepare for inches of rain in a single rainfall.

Drying the air in the shop is important for more than the plasma. All the tools, wood, etc need dry air or they’ll be a mess.

It all comes down to money! If it didn’t we would all have the best of everything even if we did not need it.

That is the one that really took me by surprise as I am sure it will you too.

I just read that… very interesting.

Lots of surfing and reading opinions on dry air. It might be overkill, but I didn’t want to risk it. Compared to @TinWhisperer’s setup I feel like I went light!

Ya know, the rest of us MIGHT have known this if we could have found the manuals. But no, they’re buried in some cavern under a mountain in Western Canada, protected by an army of Sasquatch warriors!

Here is my honest opinion @CrazyCasey

Your website is like mine so so. To have a really nice website is a huge expense.

I like lots of pictures of details.

Your you tube video on your English wheel was great. I am not into unboxing vids, but you are easy to understand, talk very clearly, dont keep repeating yourself, and not to fast.

Videos are just like anything else how much time do you want to invest in them? I am sure you can improve but how much time and money do you want to invest? Do you like building more or making videos? or spending some time with your significant other

I think to improve videos much would require a much larger investment of time and money.

Videos also come with comments and you seem like a guy (a nice one) who would try and answer every question someone asks, do you have that kind of time?

Im sure you can make the videos and website as nice as you want, your the one who will make that call.

And remember I am just one opinionated old man ![]()

Here is another way to look at it. Where i live i also need a super air-drying system.

i started out with the rw45 plasma and an air hose coiled in a bucket of water to make a worm type cooler with a bead dryer after it. i made this system pay for itself then quickly realized that spending the money on an air drying system saved me time and money. you can pay for a lot when you double or triple consumable life, then the time you save trying to save bad cuts.

if you live in a dry climate you will get by with much less than i have you may need to address your air some. the guys on here have been at it a while and do know what they are talking about.

another thing to look at it is you table is only as good as your plasma cutter. then there are many factors that can affect how your plasma cuts moisture being one of them.

if i was you i would add a bead cell and a filter first and monitor how quick you beads will change colors the move on from there.

I spent about 3 hours last night researching desiccant bead filters, and I’m at a total loss.

That post from Jim Colt of Hypertherm over on the Plasma Spider site is hard to ignore. He talks about CFM getting choked down in the quest for “perfect” air as being a real issue, and the more I research, these high-end desiccant dryers all seem to kill air flow (15-40scfm max). The only dryers that aren’t advertised at low SCFM values are the Chinese versions, whether or not their airflow data is even factual, suggesting, as many users have commented in product reviews, that they don’t do much to dry the air.

The way I see it, I have three options:

-

Spend ~$500 on a drying system to “fix” a problem I’m not even sure I have, at the expense of airflow.

-

Spend ~$200 on a Chinese drying system to “feel like I may have fixed” a problem I’m not even sure I have, at the potential expense of airflow, IF the dryer even does anything.

-

Hook my cutter up per manufacturers recommendations and hope for the best.

What a frustrating process!