I am wondering if y’all need an air dryer and filter unit for the air compressor for the operation of the Razor 45 or does either one work?

I am trying to set everything up now, all read is horror stories of that Razor Weld 45 machine.

I work with plasma every day and didn’t leave anythin to chance. I purchased a hypertherm 45xp w/cpc ordered a air dryer because I live in the northeast high humidity.

This post says alot about the importance of dry air.

http://forum.langmuirsystems.com/t/machine-freezes-in-middle-of-cut/2474?u=john543

I have an EDGE Industrial Desiccant Dryer I got on Amazon ($39) attached directly in front of the air input of the Razorweld and have no issues with air or the torch.

what size should I buy meaning connecting input if i were to attach it directly in front of the razorweld 1/4", 1/2" ,3/8"?

I got the 3/8" version. Grabbed a few pipe fittings from Home Depot and hooked it up. Could have gone tighter to the RW but this gives me room for the cord not to smack into it and allows me to easily unscrew it to replace the dessicant. It came with 2 fills so I can have one in and one recharging/recharged. It’s blue and turns pink when it needs to be changed. It can be recharged (dried out) in the oven. I have a few pounds of it though because I use these on my RW, powder coating gun, blast cabinet, etc.

Hows it working for You?

I’ve been using the motorguard filter been working great it’s nice you can take it apart and dry out the roll inside.

Just living in Phoenix Arizona we don’t have too much humidity

Hey @bsulley22! Glad to see you’re still poking around here.

For those not around in the ‘early days’ of the company (i.e 10 months ago), bsulley22 was the first ever order we ever received as a company.

Yes still trying to keep up on here. Been on the road for work the past months so haven’t been able to use the machine much.

This was an old favorite

Considering the rain/snow And the only time my shop is heated is when im out there, my set up is working great. I just took the crystals out of the oven a minute ago. Changed them 2 times since i got it in dec. ( and only on my second tip). The 2 filters have a water drain valve wich always has a little water in them. But that means the setup is doing there job. Im saprised they do work so well beens I always have something in there dripping melting snow. I plummed it with hydraulic fittings so i can disasemble it all in prob 2 minutes if needed.

Compressed air dryers seem to be back in stock at Harbor Freight.

I’ve got the same dryer and a motorguard at the cutter. It works great. Motorguard at the cutter is dry as a bone.

I got an aftercooler with water trap before the tank on the compressor.

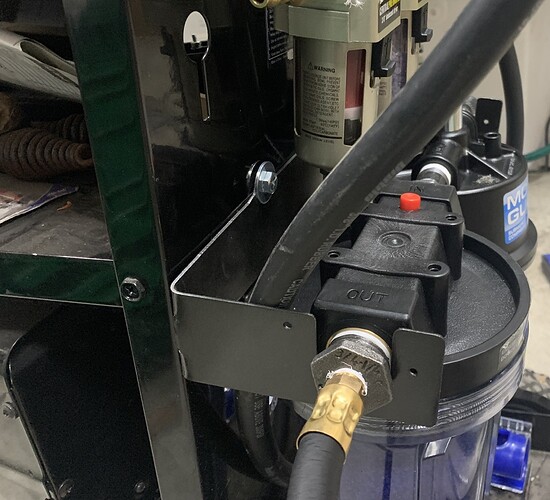

Then I just installed this monster before the cutter… the smaller 2 stage is what I’ve been using but decided to just leave it inline. Will cut some stuff out in the next few days and will report back. gonna try to modify the motorguard mount in fileshare to accommodate both units.

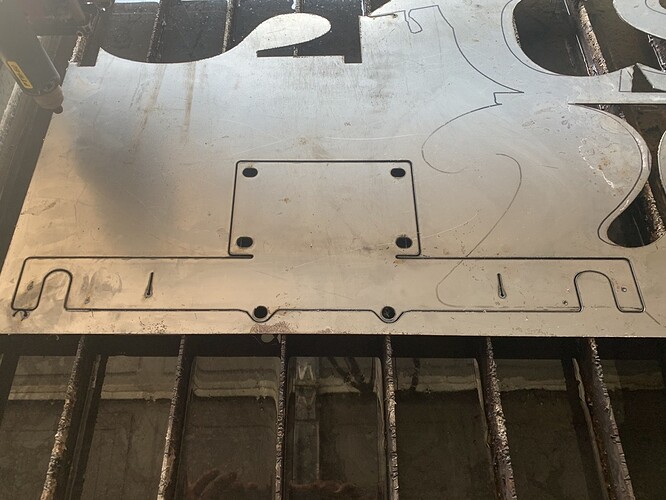

Took james5 M60 Mount design and stretched it out to incorporate the 2 units. Fit pretty good.

I cut it using the new desiccant/filter combo.

Noticed significantly less dross and cleaner cut using primeweld cut60.

Hit it with a wire wheel and lightly flap dialed to prep for paint… painted it with hammered black.

Mounted

That turned out nice - glad to see the bracket helped out! That M60 is a little tricky to mount! The design for it is on Fileshare : https://www.langmuirsystems.com/fireshare/motor-guard-m60-mount

Where did you get that giant desiccant holder? I need one and have searched a bit, but haven’t seen that one before.

After zooming in, it’s meant for water?

Wow I wouldn’t want to be around when that thing pops.