Calculator

https://www.airgastech.com/resources/calculators.html#cfm-calculator

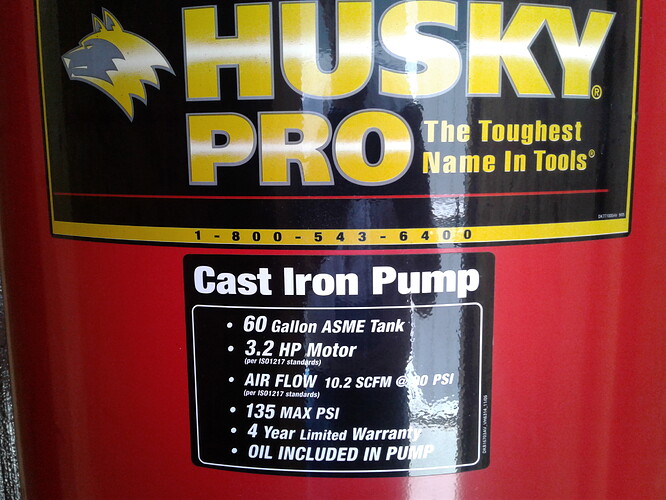

I may be crazy, but is there anyway that both numbers could be correct? It looks like they might have changed how they label and that sometimes you see SCFM and other just CFM it appears that the 11 number is CFM (in pictures above) and that the 7.6 number is SCFM. It is also strange to be that even in the picture between the 60 and 80 gallon one uses CFM and another SCFM.

Could this all be marketing to get the “highest” number?

I am not smart enough to go and do math between the SCFM/CFM but it is annoying that there is no consistency haha. Great detective work all around!

The only thing I will say is break your new compressor in by the book. I didn’t do it and it dropped a reed valve in about two weeks. Called CH and they ask if I fallowed the break in procedure in the book and I said “yep”. They sent me a new reed valve plate and gaskets.

That didn’t work so they sent me a complete rebuild kit. In the mean time I bought a new pump online because I needed the compressor and this time fallowed the book for the break in to the “T”.

When I got the new kit I rebuilt the pump and put it on and did the break in, its still on the compressor and the other one is in the box if this one fails. That was 16 years ago.

Here is a picture of the sheet on my compressor.

My opinion (worth what you paid for it) and mini rant, is this is the new world we live in.

In my job as an automotive tech (40 years) I have seen the decline in quality of parts as American manufacturing dropped off an Chinese hording of all the steel took over. We have no choice in buying overseas products because we no longer have the steel to produce nor the tooling, labor, etc. at a price to compete with China. I have read that boycotting Chinese steel production and products would affect the entire worlds economy in a very negative way, so for now we are at their mercy.

If you couple that with the greed of corporate America you end up with what were acceptable quality parts (which China can easily produce) now being barely able to pass a 90 day warranty, if the first one even works at all. EVERY PRODUCT in this category is now evaluated by engineers to figure out how to cut the cost, aka quality of a product to survive just long enough to where too many people won’t balk at it. And trust me, ALL American cars are also now made with this mentality. A $200 job is now a $2000 job, by engineering things to be so difficult that not only the DIY guy has issues (gives up) but professional techs also struggle because the caremakers restrict repair information, require special tools for EVERYTHING and generally make things a huge PITA when they don’t need to. They don’t make money on car sales, parts and service is where the money is so designed to fail is optimal, just past the warranty of course. Reputation means nothing anymore and buying based on that is foolish in today’s market, current research is key.

Remember when a 1/2 gallon of ice cream had a 1/2 gallon in it?

Bottom line is this is in every industry so when the guy says I’ve got a Husky, Kobalt or whatever brand that’s been perfect for 10-15 years, the one in the store now is not even close to the same quality so I don’t think those comparisons are valid. So your 10 year old compressor is likely made in China as well but it’s a hell of a lot better that now and probably worth keeping, repairing.

Somebody figured out these cheap compressors were lasting too long, but they will fix that!

Wow, that just spewed out of a nerve that was hit, sorry but I’m done in the garage for the day, still getting ready for this table to arrive, cleaning, doing air lines, electrical, etc and just sitting on my butt now.

from what I remember the bigger Harbor Freight compressors (central pneumatic) use pumps made in Italy for whatever its worth…

I agree, seems many things have lost the quality they once have. That’s why I just found an old craftsman for $45 hahaha

Also, this is why we need our machines, sitting here waiting makes us spend too much time on these forums and looking at freaking compressors! We are closing in on 100 comments on this thread haha.

Yes, it’s interesting to me how when I pose a question I assume everyone already has the answers because no one else has asked, only to find out there are many in my position. It’s awesome that we are all here for a like minded topic and don’t have to deal with things like “don’t you know how to use the search function”. I have been crucified for asking the simplest of questions in other forums. Ignorance should never be misconstrued as stupidity.

ig·no·rance

/ˈiɡnərəns/

noun

- lack of knowledge or information.

quick question, i came across a broken 25 gallon air compressor. i wanted to use the tank as a reserve to my main one to basically have a bigger tank combined. Will it lower the cfm’s any or will it stay the same if i add it?

The CFM/SCFM ratings are for the pump. They won’t change with a bigger tank or multiple tanks, you’ll just have a bigger reserve.

I added a 32 gallon tank downstream of my two compressor set up. It slows the air through the other tanks and lets more water fall out. I get almost no water in the receiver tank because it stays longer and cools in the main tanks.

I ordered the PowerMate 80 gallon, single stage(14 cfm @ 90 psi) last Friday from AirCompressorsDirect.com. It is supposed to ship in the next 7-10 days. I made room in the garage for it on the opposite wall that the compressed air dryer is located and had to add another 28 feet of 3/4 inch copper pipe to the air supply so it would be tied into the previously installed supply to the compressed air dryer.

A triple cylinder single stage? Definetly have some volume. ![]()

My PowerMate was shipped today from Minnesota to San Francisco Bay Area! Can’t wait to give a review of it’s operation. Wow! 80 gallons at 14 cpm! Should do a great job compared to the 30 gallon Kobalt I have today. It should get here next week. Almost 400 lbs. I ordered lift gate service for the truck. Have to talk to guys in my neighborhood to help muscle it into my garage. My driveway is on an incline, I have a power winch and furniture dollies to get it into the garage. I have a 3 foot by 3 foot area in my garage for the compressor. It is 77 inches high! I already installed the 30 amp 240 volt service for the compressor.

That should probably do the job…:)

I bought a used craftsman pro 80 gallon specs were:

175psi max 5.5HP 80 Gallon twin cylinder (two stage)

Air Delivery: 17.4 scfm @ 100psi 16.9 @ 175psi

Rigged an after cooler on it with a moisture separator after the cooler and before the tank, another moisture collector at the output also bought the HF air dryer but haven’t hooked it up between that and the plasma.

Ok Compressor related…sort of…we need to take it off the pallet, get it bolted into the concrete. So we only have my husband and me, so we can’t walk it off like we have seen in youtube videos. (we just moved here a few months ago and don’t know anybody). We do have a Harbor Freight 2ton fold up shop crane. we cut the skid a little in the corners to get the crane almost over the center above the compressor, but with a chain looped up at the top through the welded area, I think it will squeeze the components on the top. sooooo…any ideas before we unbolt it and try to lift up so I can pull out the pallet? shoud we weld a pipe through the open area and attach the chain to make it wider ? or will a 2x4 with holes slid into that area be strong enough? any thoughts, throw them my way. thanks in advance, Lisa

Shop crane should be a good help if you can get it strapped in. Just need to get enough lift to get the pallet out of the way. A webbed strap vs a chain will save some paint and may be easier to secure. When I walked my compressor off the pallet, I broke the drain valve on the bottom so be aware of that. Took me a few days to get a new one. Some folks leave the compressor on the pallet…

I put mine on these pads:

They work great. I didn’t bolt down, but may in future.

You’re almost there. Cut off the ends of the pallet that are past the compressor. Then bring the crane in from the other side than you’re on. (Right angle to where it’s coming from in your picture.)

I made some of those pads from pieces I cut from an old truck tire. Works great! I didnt bolt it to concrete, but I did safety wire it to the wall so it cant tip over. I marked the floor with a sharpie and it hasnt moved in over 2 years

Hey guys, we did it! Our neighbor dropped by as we were strapping it in and helped! Thank you all for your advice and support …Lisa & Andy