I don’t know about nitrous, but one could put a VFD and larger motor and overclock it. Compressor may not hold together long…

I have been thinking about a turbo between the compressor and tank… wonder if that would keep the pressure in the head down so I can add a after cooler.![]()

![]()

![]()

![]()

![]()

![]()

![]()

If you add a turbo you should really think about adding an intercooler… but after the tank… ![]()

![]()

Or add a very large pulley to the motor and or a very smaller pulley on the air pump. That will get those rpms up.

![]()

![]()

Procharger? ![]()

Come one you can do a little better or bigger right.![]()

I think this size is just about right so @toolboy could still mount on the wall of his garage.

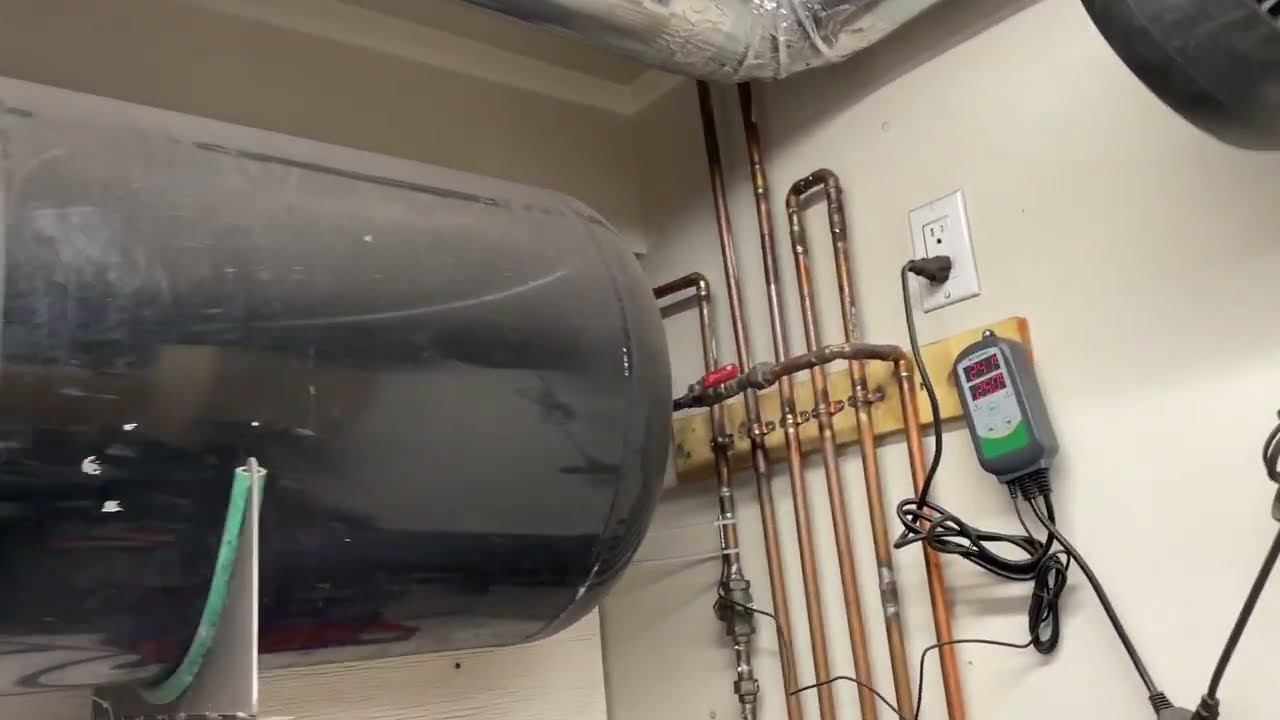

See: He has lots more room!

We don’t want to run out of air mid cut. Table may throw a error code.

Lol, no kill like overkill!

Although having a compressor like that, youd need to run it for 3 or 4 seconds once a week to satisfy your needs. ![]()

I think that is the machine @Bigdaddy2166 is running.

This is my badboy… Had it for many years.

Almost 30000 hrs on it. I bought it at an auction for $1500.

Had one of those on our batch plant. Nothing but problems with the latest versions. The older models were great.

This is my desiccant traps after half an hour of combined pneumatic angle grinder (2hp motor), die grinder (1 hp) and chipping gun use.

I think it’s working

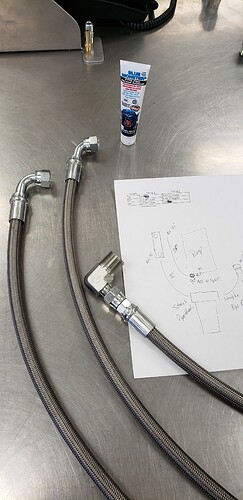

We used Hose Power (BF Goodrich company). We got 1/2 NPT braided/teflon hoses rated to 500 degrees. Not that expensive.

Can you confirm which 1/2 ones you used. All the research I’ve done you can use them. I’m trying to get mine up and running. Did you ever post the pictures?

@Sticks

Is there a write up of what you are using?

@jtcweb if you type the @ sysmbol you can direct the comment directly to whom you are looking for information from. They will also get a notification.

This is a 2 year old dead thread.

What specifically are you referring to?

My desiccant traps are NOT recommended***. They are whole house filters in series with a piece of PVC pipe running to the bottom as the inlet to force the air to travel through the desiccant.

*** Safety issue. not designed for compressed air, although rated for 120psi, that is water pressure, not air pressure and a failure of the container could cause serious injury or DEATH!!!