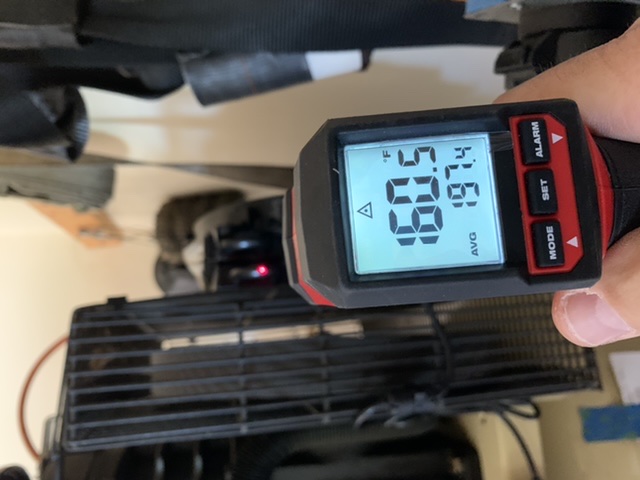

Brown fox this is what I am getting on my system after letting the compressor run and cycle for 45 minutes with the fan set to come on and off with the activation of the compressor.

The ambient temperature here today is 82F

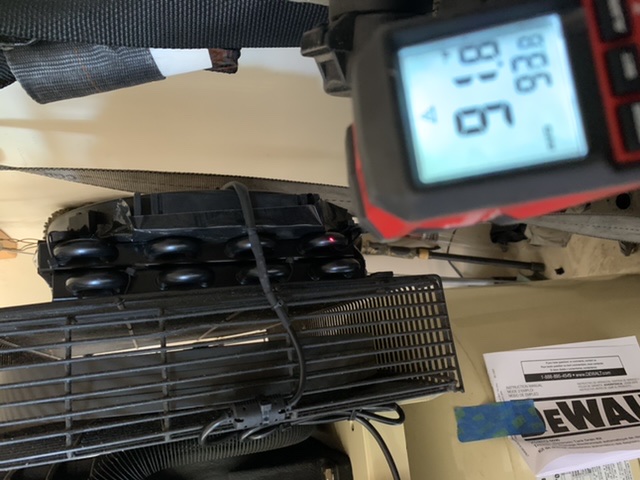

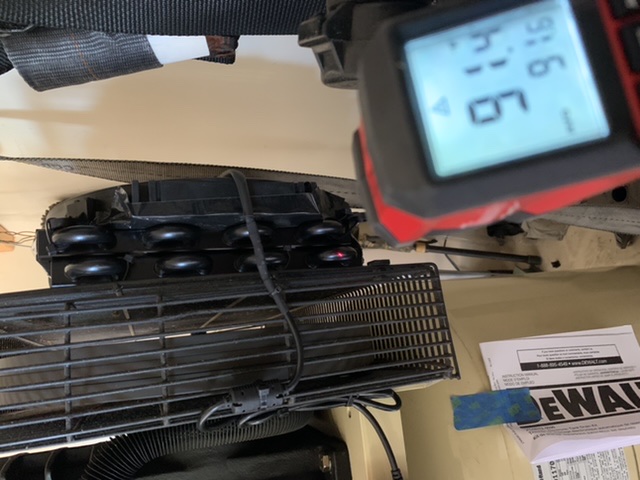

As you can see as the air moves through the after cooler with the fan, it gets cooler and cooler at each stage. You definitely have to have a fan of some sort in order for it to be productive at all.

Edit

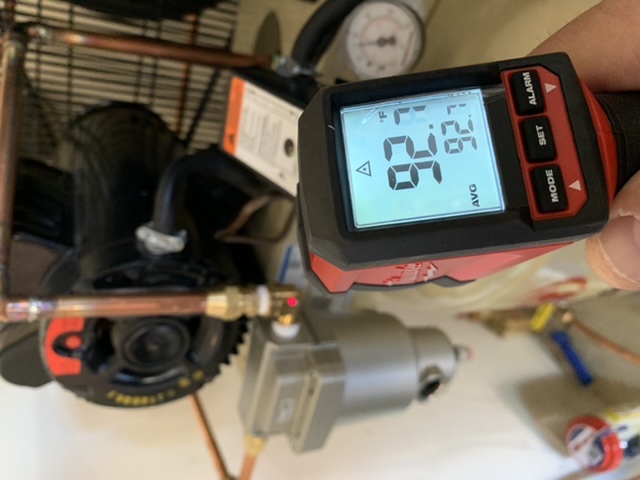

“Dang, i just realized thats a 190deg difference from output of compressor to going back into the tank. The water separator is also pulling out a lot of water which otherwise would be going into the tank”.

Sorry for pictures being sideways. The forum is doing this.