It must be my day! One of my goals was to do some 30a tip cuts on 20ga (aka fine cut) to see how that does. I spent the first 10 minutes trying to do a straight cut to clean up my sheets to cut, and it wouldn’t cut for anything! THC on/off, different speeds, etc…tried them all. It would cut a few inches and lose arc. After some head scratching I walk over to the plasma and notice that I forgot to hook up the ground lead. Duh! Ok, I’m learning…cut me some slack…lol

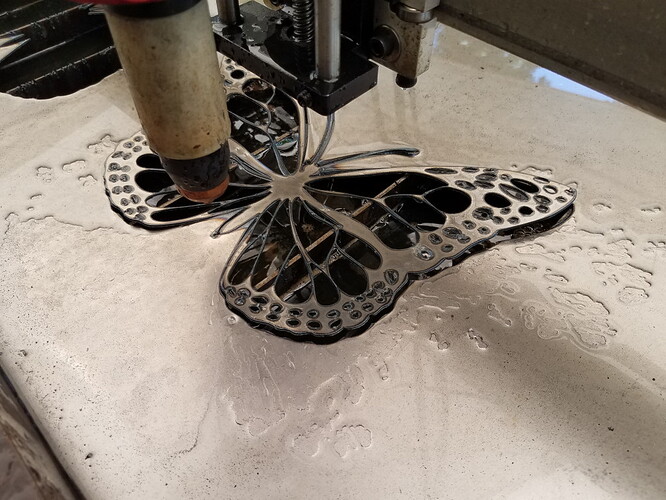

Did get a nice piece, though!

Still some work to go on pierce timing and I’m writing off my first 5 tips and electodes lol! But pretty happy how that came out considering the fineness / closeness of the cuts. It’s for my daughter, I think she’ll like it!