Simple enough to modify an existing one to add this and it saves the additional step of processing the GCode file. I’m not criticizing your method, whatever floats your boat, but I do disagree with your statement.

Ok I am looking at cutting 50 parts in 1/2" material and concerned about duty cycle. I use Fusion so I cant create a pause like you you can in sheetcam correct?

I am aware I can do this manually with fire control but would rather automate it.

So I was looking at this program and downloaded it but not sure how to run it?

Anything else you would like to add I am all ears.

Maybe this is a bad idea for me if I can’t even figure out how to run the program?

Which program are you talking about???

Fusion 360 does have a manually insert pause.

But I’m not sure if the post processor picks it up or not?

I’m out in the field today but when I get back to the computer I’ll take a look at it.

The other way to do it would just be develop your cut into three different tool paths and just run one then the next then the next use the break in between them as the pause.

What do you think about just slowing the rapid speeds way down?

That’s a really good idea as well. I’ve never done anything like that but logically it sounds like that should work .

I’m just lucky enough I could cut quarter inch at 100% duty cycle all day.

So tired just slowing the rapids down and it worked fine. Use a little more air, but its a easy way to help with duty cycle and cooling things off when cutting thick stuff.

I slowed the rapids down to about 15 ipm. You would have to do some figuring to see what speed you need to slow down to.

I have generated a significant update to this program:

https://drive.google.com/file/d/1mzzlLegrdGDh4xPaqBKSFEe9Tq2ju_ie/view?usp=sharing

To use the program, download the zip file using the link above and extract the entire folder to a location of your choice on your local computer. Navigate to the folder you just extracted and launch the GCodeInsertPauses.exe file. All 11 files must be in the same folder as the .exe file for the program to work correctly. There is no need to install the program as it will run from the folder.

Use of this program is entirely at your own risk!

NEW FEATURES INCLUDE:

-

Open *.nc files and *.tap files in the file dialog. (the modified *_pauses.nc file that the program generates is always saved as an *.nc file but crossfire will recognize that format. Your original file is not altered by the program)

-

Repeat loops with air only. Add an air only loop after each cut to clean the cutting tip and the area that the machine just cut. You can also optionally exclude larger loops by setting a limit of your choosing. Useful for cutting air-reactive metals such as aluminum and titanium.

-

Repeat loops with torch on. Handy for cutting small holes in thick sheets when the first pass may not fully ream out the hole evenly all the way to the bottom. Again, you can optionally exclude larger loops and decide whether to repeat the last loop (default is ‘no’ to avoid damaging your part when it drops away)

How to use the program:

-

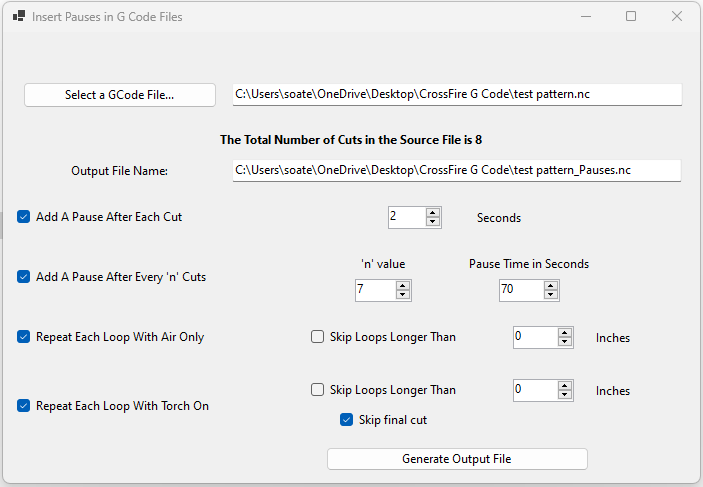

After extracting the folder, launch the *.exe file and click the ‘Select a GCode File…’ button. Find and open your G Code file. The program will analyze the file and let you know how many cuts it has.

-

Check the ‘Add A Pause After Each Cut’ check box and select a pause time using the numeric up/down box to the right of that check box. Default is 2 seconds. Uncheck that box if you do not want to add a pause after each cut

-

Check the ‘Add A Pause After Every ‘n’ Cuts’ if you want to add a longer pause after a certain number of cuts have been performed. Use the numeric up down controls to the right of that check box to set the ‘n’ value and the pause time in seconds. Default is n=7 (inserts a longer pause at the end of every 7th cut) and pause time of 70 seconds because those numbers work for my compressor! Handy to allow an undersized compressor to catch up. Default is 7 for the n value and 70 seconds. Uncheck that box if you do not to want to add an additional pause after every n cuts.

-

Check the ‘Repeat Each Loop With Air Only’ if you want the machine to repeat each cut with the torch off. Also check the ‘Skip Loops Longer Than’ box and set a value in the corresponding numeric up/down field if you want to skip this for larger loops.

-

Check the ‘Repeat Each Loop With Torch On’ if you want the machine to repeat each cut with the torch on. Also check the ‘Skip Loops Longer Than’ box and set a value in the corresponding numeric up/down field if you want to skip this for larger loops. Finally decide if you want to skip the final cut by clicking that check box.

-

Once you have configured all of your options, click the ‘Generate Output File’ button. A new file will be created with your original filename and _pauses.nc appended to it. It will be saved in the same folder as your original G Code file.

How It Works

Upon loading your file, the program scans for ‘G0Z1’ codes which occur at the end of each loop. It accumulates these and gives you a total number of cuts.

It generates a new file which essentially copies your original file one line at a time but after each ‘G0Z1’ it inserts a ‘G4PXX’ to add your pauses.

For the air only loops, it stores the lines from each loop in a temporary string variable. It looks for the H0 command at the end of the loop and then inserts an M5 after that to shut off the torch. Then the motion lines G1,G3 and G4 are repeated after that to complete the loop again while the tool is cooling down after the cut with air only.

Similarly for the repeat cut loops, the motion lines are repeated but the H0 and M5 commands are moved to the end of the new loop so the torch stays on.

Limitations

-

Results will be unpredictable for G Code files with no lead-ins as the program assumes you have a lead in line and omits it for the repeat loops.

-

The air only feature relies on the cooldown period of your torch. For the Razorweld 45 this is 30 seconds so this suitable for most loops. For other plasma cutters, you may need to manually adjust your cooldown time.

-

The air only and repeat cut features of the program also may not work for non-THC enabled GCode files as it is using the H0 and H1 commands to identify the start and end of the cut loops. Those features have not been tested on non-THC G Code files. The pause features should work fine for non-THC G Code files.

Let me know if you have any questions or comments. Happy cutting!

How do you do this? My Plasma Cutter only turns on Air with a Torch On command.

I’m using the Razorweld machine supplied by Langmuir Systems. It has a 30 second cooldown after an M5 code is passed and the torch stops. During that time, air continues to blow so I’m taking advantage of that in the code for this program. If you don’t have that plasma cutter then this feature might not work for you.

it’ll work with others that has a dial to set the time the air stays on . you just have to set it to a longer delay.

So it turns on the air after you issue an M5 even if there wasn’t an M3 command?

no, it just continues another loop once the torch shuts off and uses whatever air delay you set your cutter to.

so if you set the air delay to 20 seconds to cool the tip, it’ll continue another loop until the air shuts off after 20 secs.

Not quite. Your original code will have a series of cut loops starting with an M3 and ending with an M5.

The ‘air only’ feature does the original loop with the torch on, then adds an identical loop after the M5 code for each original loop. The lead-in is not copied.

For example, if the loop is a simple circle, the torch cuts the circle and then shuts off, the circle morion is then completed again before moving on to the next loop

Also this program assumes you have a lead-in on each cut. If you do not have a lead-in, results may be unpredictable. I haven’t tested it with a g-code file containing no lead-ins

Ah ha, yes, interesting. So, yeah, that would work with any Plasma Cutter, only some wouldn’t push air through the tip for more than a time determined by the PC needs. My PC runs the air (after cut) based on it’s algorithm for cooling needs - ie, how long has the torch been on.

FWIW, the description might be ‘adjusted’ so this behavior is clearer…

I have generated another revision to this program. There were a couple of bug fixes. Additionally, I added a ‘dwell after plunge option’ for cutting thick materials.

I cut a lot of 1/4" steel and aluminum. I find with the razorcut 45, the torch doesn’t always fully penetrate the material before starting to travel. This causes premature tip wear. With this update, the torch can be set to pause for a selectable time period after plunging into the stock. I find 0.5 second pause after plunging into the material works really well for 1/4" stock, so that is the default value in the NumericUpDown control for that feature.

Below is the link to the latest update, for anyone interested:

I found your post and it is exactly what I need! I downloaded, installed and tried the code, and it creates a file but there are no updates done. When I load the source file it says “The total number of cuts in the source file is 0” I can clearly see the M5 in the source file… Am I missing something

Thanks,

Bud