im lookingbfpr settings for my 65 sync hypertherm for 3/4" steel. i installed the 85amp tip and used book settings but its not even piercing all tue way through. i upped pierce delay and slowed machine down with no improvement. i ttpically cut 16 ounce copper and 26 gauge steel so i dont have much experience with thicker metals. is there something im missing?

What cut settings have you tried?

@Clipper581 Welcome to the forum.

Did you turn up the amps on the machine ?

How long of a pierce delay are you using?

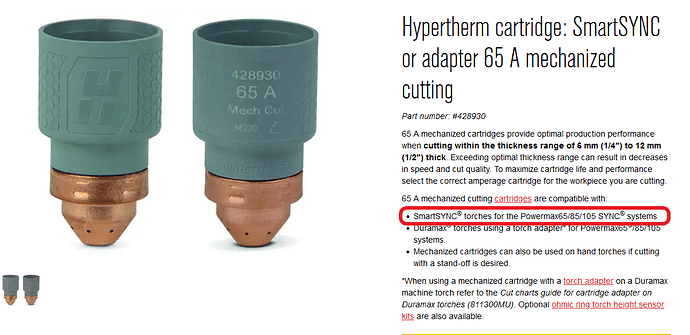

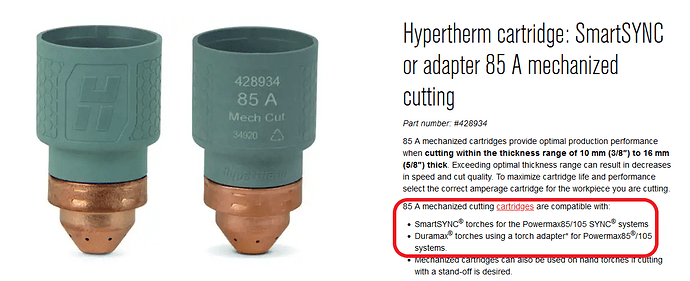

Could it be beCause you have a 65 sync with a 85 cartridge? Not sure how the plasma would act in that situation.

You might be on to something Phillip. Hypertherm suggests the 65 amp cartridge is applicable on the 85 amp sync machine.

But it does not list the 85A compatible with the 65A machine:

Maybe I am not sure. The sync machines are supposed to read the cartridge and preset air and amps for you… I just wonder if the machine knows what to do. . I don’t really see how one could benefit from 85 amp consumable on a 65 amp machine other than just having them on hand…

I almost bought a sync when I bought my 65 . The unknown like this is why I held out.

Thanks for the reply, I wondered the same myself about the 85 cartridge in 65 sync. The weird thing in the hypertherm cut charts guide you would think they would define more clearly what cartridges work with what machines. I was under the impression to optimize cut quality you would use corresponding cartridge and the machine would recognize it and adjust settings. I do know if you do not power cycle the machine after switching the tip, it will throw a fault. I would think it would do the same thing if it recognized the tip that was not made for the machine. I will swap to a 65 cartridge and do an edge start like the book describes to see if that improves my situation.

I thought I read the sync’s done away with the need to cycle the power. I know I have to on the older 65. You can predill a hole if you need to pierce. It is hard on the consumables you may be able to pierce 3/4 you would probably want a little higher pierce height. I have pierced 3/4 with a rw45 before.

The cartridge may not be your issue or all of it.

A 65 amp plasma cutter can not put out 85 amps just because you put 85 amp consumables on it.