I am on the pre order for the pro table. I also own a tormach cnc mill with a Bolt on 4th axis table. I have been thinking about figuring out a way to bolt the 4th axis to the crossfire pro so that I can cope tubing on the plasma. Do any of you guys have any experience with something like this? Any tips or trick or input would be awesome! Thanks in advance

I am interested in the replies for this. I’m almost in the same boat as you, I just don’t have my 4th axis yet. You have an 1100?

You guys happy with those mills?

Yeah I have one if the first 1100’s I wonder if the new crossfire software will have provisions for A axis?

The mill is pretty good, I wish mine had a higher spindle speed (5140rpm) and was maybe just a tad bit more rigid. But I understand it’s a hobby grade machine and so with that being considered I like it. They do have the new model that will do 10000 rpm which I desperately wish mine would do. With the slower spindle speed the cut times just get so long that it makes it basicly impossible to do any production type work on it.

My Tormach is also an early model, serial number 325 built in 2007. I plan on upgrading it to have the newer VFD so i can have the 5100 rpm mine is currently maxed at 4500 rpm. I got my mill for so cheap I cant really complain ($3600) It seems to do what I need/want right now and there is/have been people that started businesses or do small run production (a couple you tubers John Grimsmo, NYCCNC) On cnczone I’ve seen people using these machines for production as well.

@Pangeaspeed do run PathPilot or Mach?

I mean he asked what I thought about the machine and that’s my honest opinion.

I am not going to argue that you can or can’t do production work with it… it’s just not the way I want to do my production work in my opinion.

I am runnin Mach 3

Word! Wasn’t arguing either and respect your opinion, sorry to sound that way, it’s always hard to determine people’s intent based on a short comment, it can end up as conjecture. The way I learned about Tormach was through CNC Zone, Grimsmo and Saunders, so in my opinion it’s a cheap viable way to achieve production and that’s what I was trying to convey as my opinion. My opinion your opinion, neither right nor wrong, just ours. My apologies, I really should spend more time on my comments. Hopefully someone can chime in on the 4th axis I would really like to hear from someone that has done this. And I’m definitely going to pursue this once I get the pro table up and running! Which 4th axis do you have for your Tormach? There seems like there might be room where the Y axis homes on the pro, otherwise it would have to be where the water table is, so a water tank for the table so it can be drained then and A axis dropped in. Or could there be an extension on the Y axis past the water bed for this function, totally spit balling here not sure if this is feasible just starting conversation.

Look at cnc wrapper. I sould help you with this

@Appletreedude I was thinking it would be pretty easy to make a bracket on the edge of the table that it could bolt too or like you are saying maybe it drops down in one of the corners? A friend of mine was saying that it wouldn’t be too tricky to plug it in as either the x or y axis if there isn’t a provision to run an A axis.

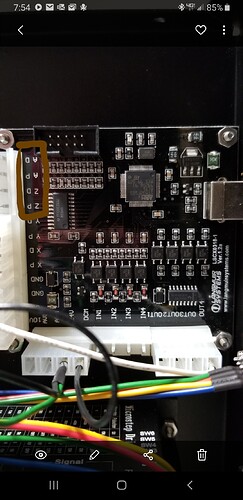

Oh hell yes! That is really good info! I really appreciate you sending that photo