Is 40 Speed too slow for 1/4” steel, 50amp ? Everlast 52i

47 ipm is what I use.

Thanks! I’ll try speeding it up

Also make sure your using a 1.0mm/50 amp tip not a 1.1mm/60 amp tip and set flow air pressure to 70/75psi.

are you cutting straight lines or small holes? I normally will run different speeds for profiles vs holes. whatever speed cuts really great in the material in a straight line I cut that speed by 20% - 40% of I’m going to cut a hole in that same material.

Down side is the hole will have lots of dross but at least it will be sized correctly.

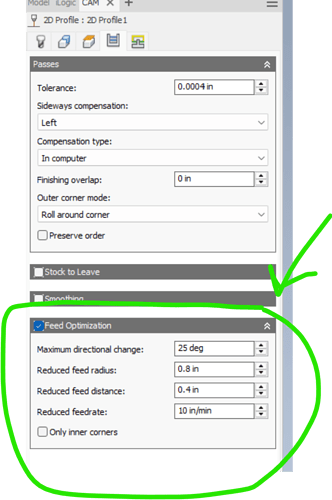

you can also use this feature and it will automatically slow down for holes and other radiuses.

Also these values are the defaults (in the screen shot) you’ll need to play with these settings to find what works best for you.

Thanks. I’m sure I’m using the 1.0 tip. However after changing the electrode and tip before this cut, it only lasted one project before it burned up. That’s why I was thinking I’m going too slow and it’s creating too much heat. I also use a fan blowing /venting across the table. It’s several feet away.

I have a good 70 PSI through the cut as well.

Oh that’s a great feature. I’ll try some more cutting. I’m mostly doing straight/radius cuts but do have holes. I could see using this feature.