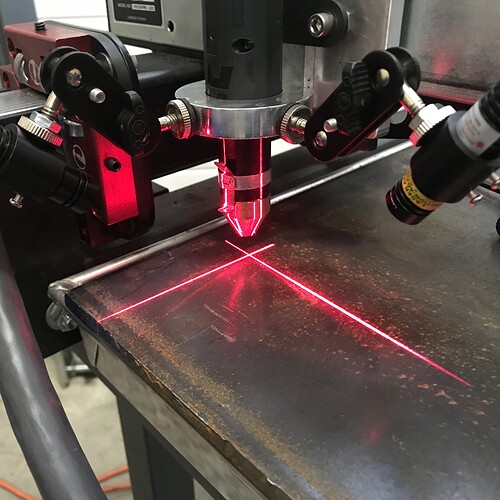

Cutting my first project out of 14ga mild steel using my Hypertherm 45XP at 45amps/225ipm feed rate. The mounts @Lil_Abners_Kustoms made me work great for holding my machine torch! This table is cutting great and is officially ready for full production.

Are you using fine cut consumables?

No, that is using the regular machine torch consumables. I have some fine cut but I haven’t tried them yet. These consumables cut well until it gets to the really small bits so I’m interested to see how much of a difference the fine cut will make. For 90% of my cutting these will be perfect. The feed rate/cut quality is impressive and has been money well spent.

oooooo…love that.

It’s got to be way faster than the manual method. I use a red laser on the Redsail CO2 laser for adjusting the home position and it makes things pretty quick & easy. Hadn’t considered doing that with the Crossfire.

Those are pretty big looking lasers though - or is it just the close-up effect?

The angle on the photo makes them look a bit bigger then they actually are, but they are larger than they need to be. Just cheap 10mw Chinese things off eBay. I’m still trying to decide if I want to use the adjustable part of the mounts or just put the laser holders directly onto the torch mount.

I have a laser mounted to the head of the Redsail laser cutter and it gets in the way of cleaning the lens. I would think the same thing might happen here - mounted directly to the torch mount you might find yourself knocking them out of alignment every time you adjusted the torch height.

I like the adjustable mounts. Once set in place, a drop or two of green Loctite should keep them in place. Green Loctite will seep into the threads of an already screwed on fixture (vs blue or red where you need to put it on the threads before joining the parts).